Blog

Communication Protocols in Instrumentation: A Comprehensive Guide

Here’s the text formatted for MS Word, incorporating standard heading styles and bullet points.

Communication Protocols in Instrumentation: A Comprehensive Guide

Communication protocols play a crucial role in instrumentation by enabling devices to exchange information efficiently. This article delves into various communication protocols essential in instrumentation, including HART, Modbus, Profibus, Fieldbus systems, and wireless communication. We aim to provide a comprehensive understanding of each protocol, along with their functionalities, benefits, and typical applications within automation and instrumentation frameworks.

HART Protocol

Overview of HART Protocol

HART (Highway Addressable Remote Transducer) is a widely used communication protocol in the field of process automation. Introduced in the late 1980s, HART was designed to facilitate two-way digital communication between field instruments and control systems while maintaining compatibility with traditional 4-20 mA analogue signals.

Features of HART Protocol

- Two-way Communication: HART supports both master-slave and peer-to-peer communication, allowing devices to send and receive information.

- Digital and Analogue Signals: It operates over existing 4-20 mA loop connections, combining digital signals with analogue data.

- Device Configuration: HART enables remote configuration and diagnostics of field instruments, enhancing maintenance and management.

Functionality

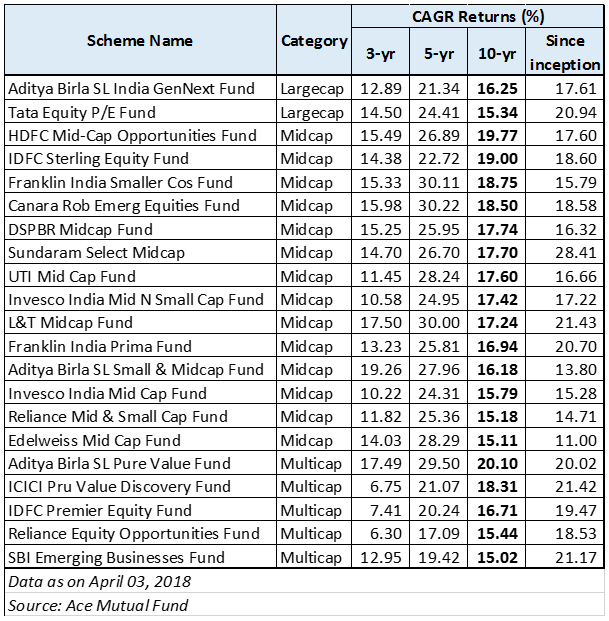

HART enables users to read sensor data, configure devices, and perform diagnostic tasks without the need for physical access to the instrument. This is depicted in the diagram below.

HART Protocol Communication Flow

Applications of HART Protocol

HART is commonly used in various applications within process industries, including:

- Flow Measurement: Used in flow meters for performance monitoring.

- Pressure and Temperature Monitoring: Applied in safety and control systems.

- Level Measurement: HART-enabled level sensors provide critical data for control applications.

Modbus and Profibus

Introduction to Modbus

Modbus is a serial communication protocol originally developed by Modicon (now part of Schneider Electric) for industrial applications. It provides a means for devices to communicate over a network and has become one of the most widely used protocols in industrial automation.

Features of Modbus

- Open Standard: Modbus is an open protocol, allowing interoperability between devices from different manufacturers.

- Master-Slave Architecture: In Modbus, communication takes place between a master device (e.g., a PLC) and slave devices (e.g., sensors, actuators).

- Multiple Variants: Available in different forms, including Modbus RTU (Remote Terminal Unit), Modbus ASCII, and Modbus TCP/IP.

Introduction to Profibus

Profibus (Process Field Bus) is another important communication protocol, designed by the European Committee for Standardisation (CEN) and widely used in factory and process automation.

Features of Profibus

- High Speed and Reliability: Supports high-speed communication, suitable for time-critical applications.

- Comprehensive Protocols: Includes Profibus DP (Decentralised Periphery) for fast communication and Profibus PA (Process Automation) for process automation applications.

- Flexible Topology: Supports different network topologies, including star, line, and tree configurations.

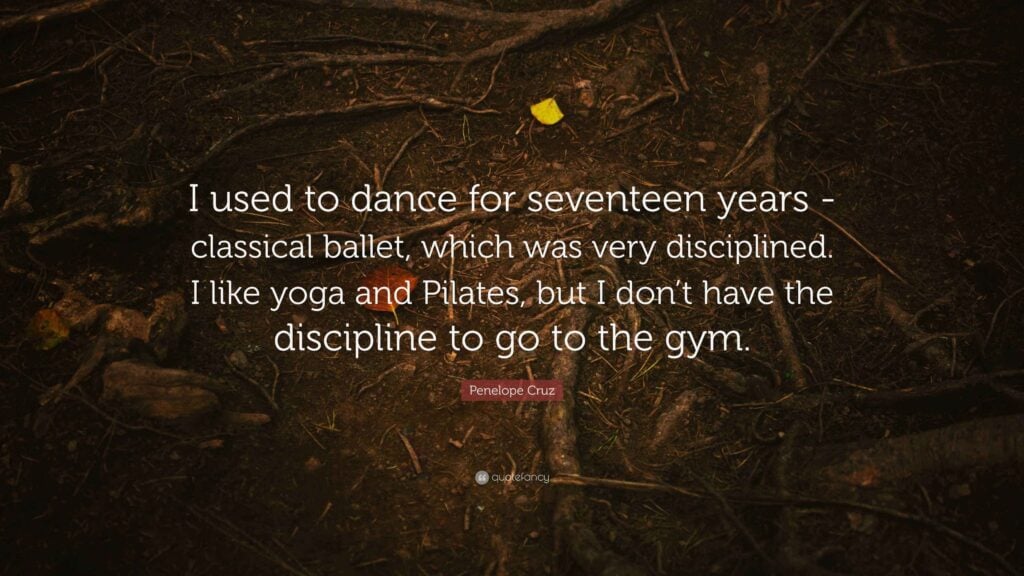

Comparison of Modbus and Profibus

While both Modbus and Profibus serve similar purposes, they possess distinct differences in terms of architecture, speed, and complexity. The following summarises their key differences:

Comparison of Modbus and Profibus

| Feature | Modbus | Profibus |

|---|---|---|

| Standardisation | Open Protocol | Standardised by CEN |

| Architecture | Master-Slave | Station-Based |

| Speed | Up to 115.2 Kbps (RTU) | Up to 12 Mbps (DP) |

| Complexity | Simple to Implement | More Complex Setup |

Applications of Modbus and Profibus

Both Modbus and Profibus are extensively used in industrial automation systems for various applications:

- Modbus Applications:

- Energy monitoring systems

- HVAC systems

- Pump and motor control

- Profibus Applications:

- Motion control systems

- Distributed control systems

- Process control in manufacturing

Fieldbus Systems

Introduction to Fieldbus

Fieldbus systems are dedicated networks that allow digital communication between various field devices and control systems in industrial environments. They facilitate the integration of smart devices into a unified communication platform.

Types of Fieldbus Systems

Several types of Fieldbus systems are commonly used in instrumentation:

- Foundation Fieldbus: A hybrid architecture that allows both field device communication and control logic execution within the field devices.

- AS-Interface (AS-i): A simpler, cost-effective solution for connecting discrete sensors and actuators directly to a control system.

- CANopen: Designed for embedded control applications, extensively used in automotive and industrial automation.

Advantages of Fieldbus Systems

Fieldbus systems offer numerous advantages, including:

- Reduced Wiring: Minimise the amount of wiring required by replacing multiple analogue connections with a single digital network.

- Improved Data Exchange: Enable faster and more reliable data transfer between devices, facilitating real-time monitoring.

- Field Device Interconnection: Allow seamless connection of multiple field devices to a single control system.

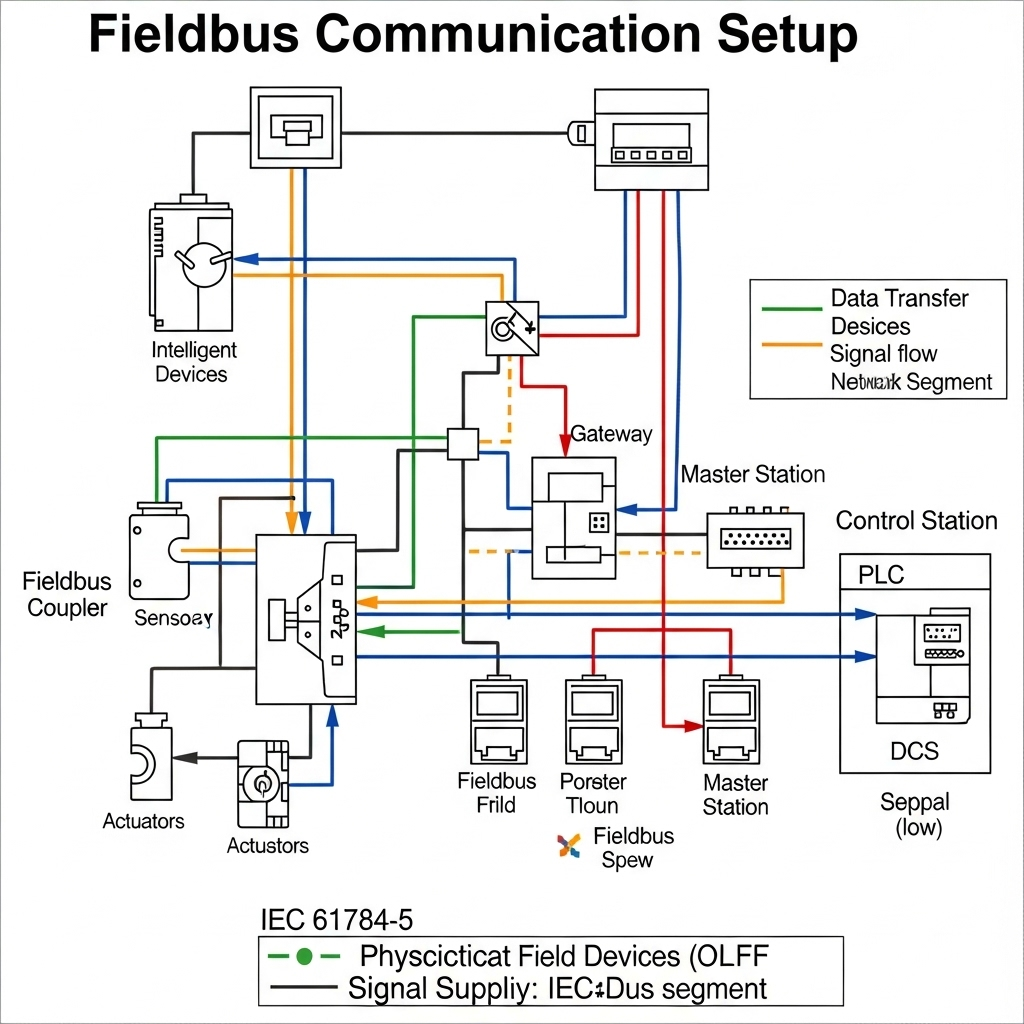

Diagram of Fieldbus Communication

Below is a representation of a typical Fieldbus communication setup, illustrating the connectivity between field devices and the control system.

Applications of Fieldbus Systems

Fieldbus systems find application broadly in industrial settings:

- Petrochemical Industry: For monitoring and controlling processes in refineries.

- Food and Beverage: Used in quality control and monitoring.

- Water Treatment Facilities: Applied for real-time monitoring and control of processes.

Wireless Communication in Instrumentation

Overview of Wireless Communication

As industries evolve, wireless communication becomes an increasingly viable option in instrumentation, offering flexibility and convenience while reducing installation and maintenance costs.

Advantages of Wireless Communication

- Flexibility in Network Design: Wireless communication facilitates a flexible layout, eliminating the need for extensive cabling.

- Cost-Effective: Reduces installation costs, particularly in difficult-to-reach areas or hazardous environments.

- Remote Monitoring: Enables real-time data collection and access from remote locations, improving operational efficiency.

Types of Wireless Communication Protocols

Several wireless protocols are prevalent in instrumentation, including:

- Wi-Fi: Widely used in many sectors for data transfer but may have limitations in terms of range and interference.

- Bluetooth: Ideal for short-range communication, suitable for connecting devices such as sensors to mobile devices.

- Zigbee: A low-power wireless mesh protocol designed for short-range communication, popular in sensor networks and home automation.

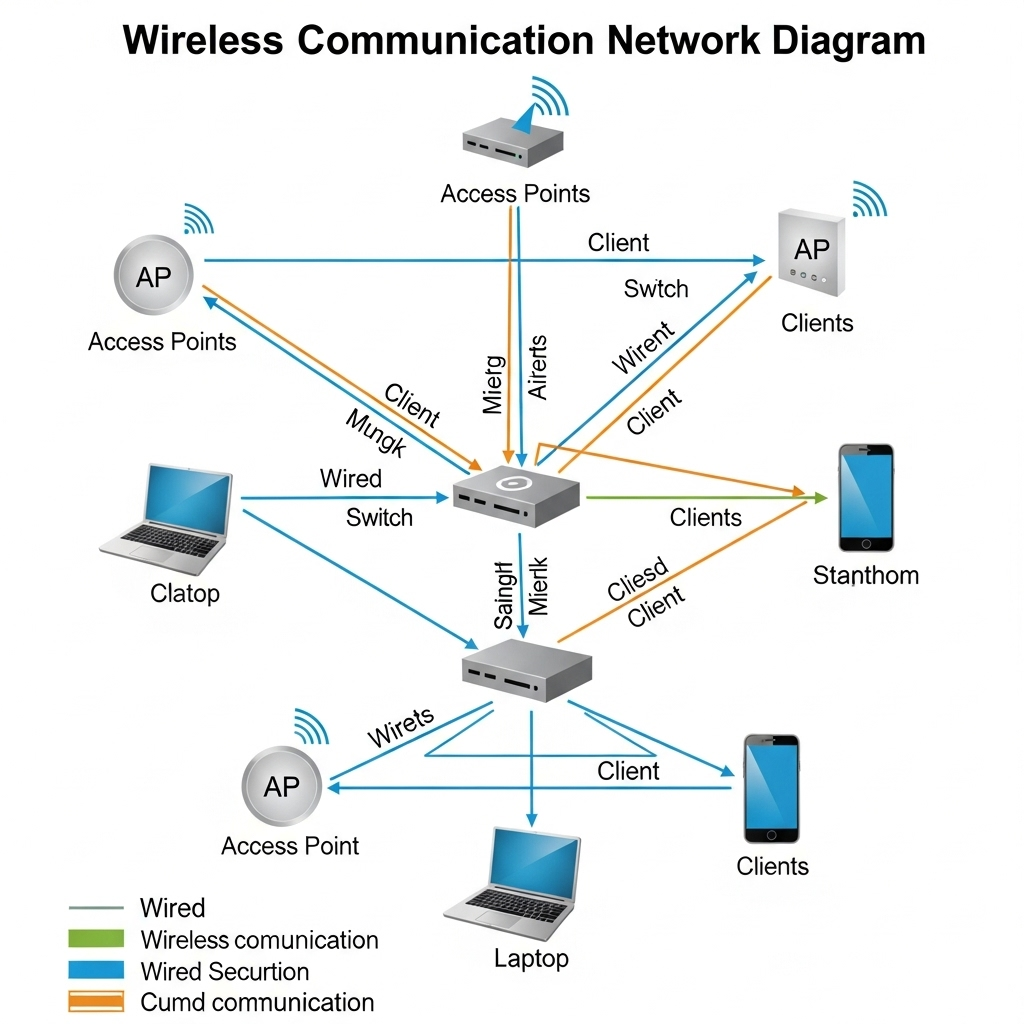

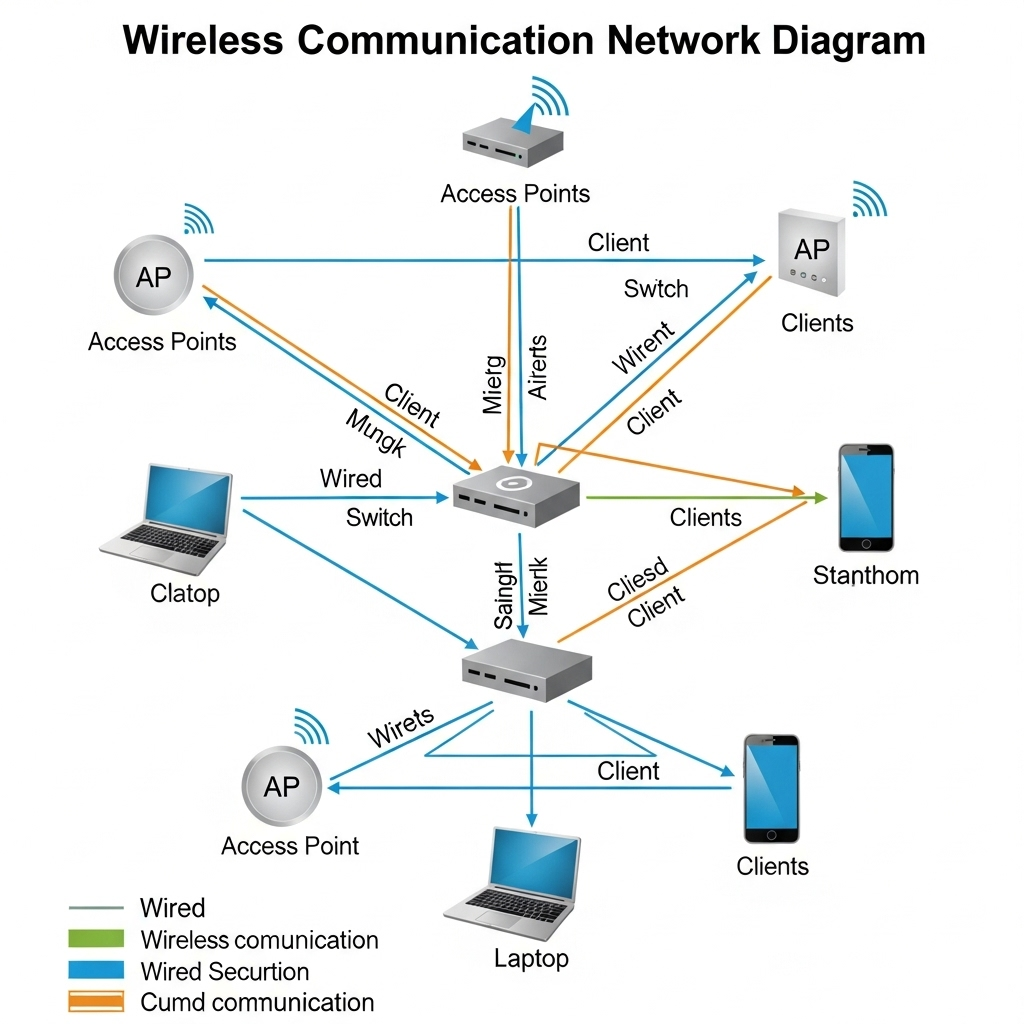

Diagram of Wireless Communication Network

The diagram below illustrates how wireless communication components interact within an instrumentation network.

Applications of Wireless Communication in Instrumentation

Wireless communication is transforming how industries manage instrumentation:

- Oil and Gas Monitoring: Used for remote monitoring of conditions in inaccessible locations.

- Smart Buildings: For real-time monitoring of HVAC systems, energy usage, and environmental conditions.

- Agricultural Sensing: Employed in smart farming to monitor soil moisture and crop conditions.

Conclusion

Understanding communication protocols in instrumentation is vital for any automation engineer or technician. Each protocol, from HART to Fieldbus systems and wireless communication, presents unique features tailored to specific operational requirements. As industries continue to innovate, the importance of these protocols in ensuring reliable and effective communication among devices will only increase. Through awareness of their functionalities, advantages, and applications, professionals can select the most appropriate communication protocols to optimise their automation systems, improve efficiency, and ensure system longevity. The information covered here is foundational for enhancing performance in any industrial context that relies on instrumentation for operations.