Deep Dive into Instrument Calibration and Maintenance

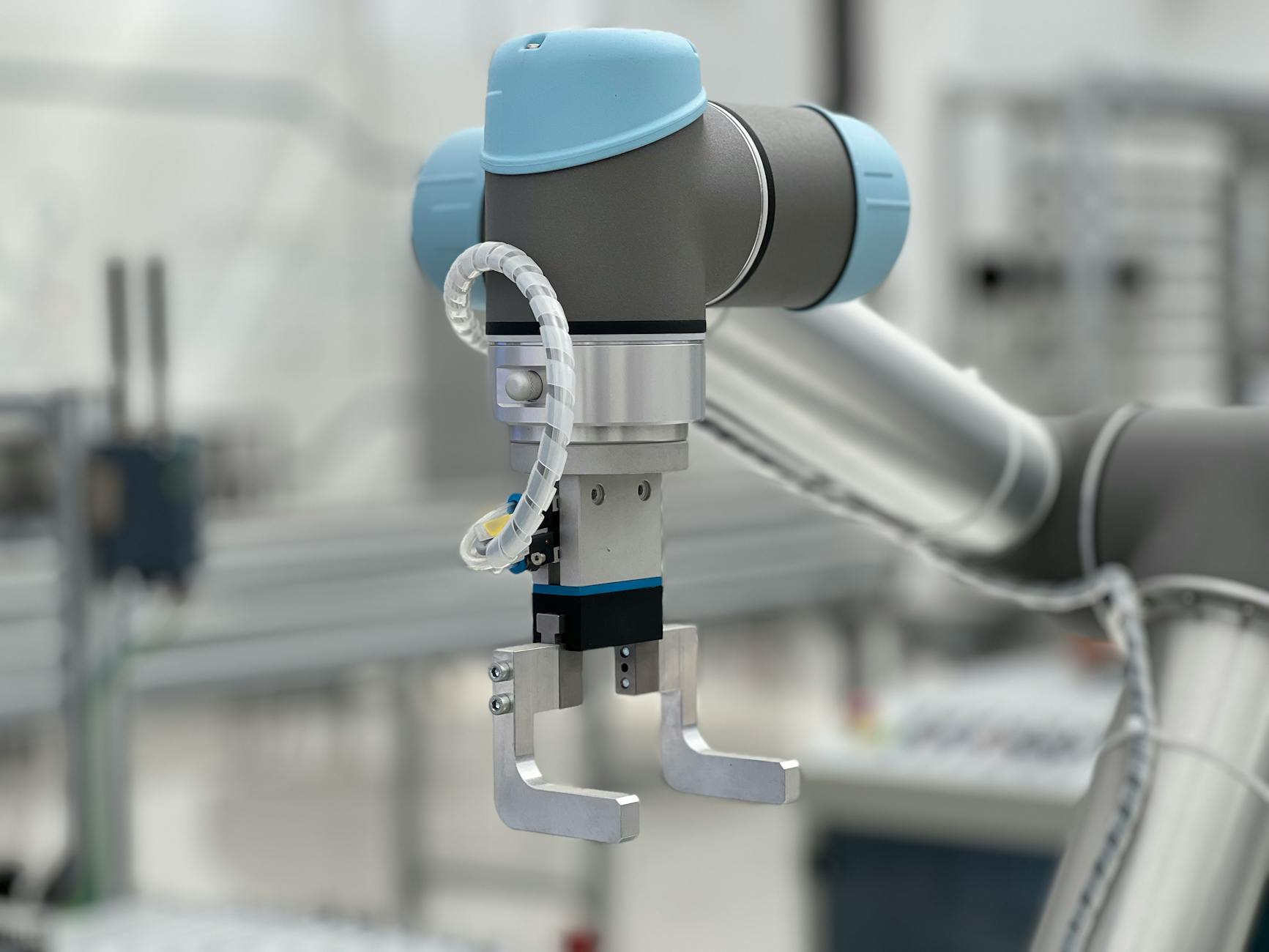

Instrumentation: The Backbone of Industrial Automation

In modern industrial settings, instrumentation plays a pivotal role in automating processes and ensuring operational efficiency. It involves the use of various tools and devices to measure, control, and analyse process variables such as temperature, pressure, flow, and level. Proper calibration and maintenance of instrumentation are crucial for accurate readings and reliable operation. Regular checks and balances allow for early detection of potential failures, maintaining product quality and safety standards.

Calibration Steps:

1. Identify relevant parameters.

2. Use reference instruments for calibration checks.

3. Adjust settings according to manufacturer specifications.

4. Document changes and re-evaluate periodically.

Maintenance Steps:

1. Schedule routine inspections based on manufacturer guidelines.

2. Clean and replace sensors as necessary.

3. Test for software updates and patches.

4. Keep audit trails for compliance and regulatory purposes.

Valve Maintenance: Ensuring Seamless Operations

Valves are essential components in fluid control systems, playing a critical role in regulating flow and pressure in piping networks. Regular valve maintenance is necessary to ensure that they operate efficiently and effectively without causing process interruptions.

Calibration Steps:

1. Verify the valve position and alignment.

2. Adjust the actuator for optimal performance.

3. Test for leaks and flow rates to ensure specifications are met.

Maintenance Steps:

1. Inspect for wear and tear on seals and gaskets.

2. Lubricate moving parts regularly.

3. Operate valves periodically to prevent seize-up.

4. Replace any faulty components promptl

Analyzers: Precision in Process Control

Analysers are instrumental in monitoring various parameters in industrial processes, ensuring that the chemical composition of products adheres to quality standards. Regular calibration and maintenance of analysers are critical for accurate measurements and reliable outcomes.

Calibration Steps:

1. Determine the calibration frequency based on service conditions.

2. Compare readings with certified reference materials.

3. Adjust calibration settings to align with manufacturer specifications.

Maintenance Steps:

1. Clean sampling components to avoid contamination.

2. Inspect and replace worn sensors and probes.

3. Keep software updated for optimum performance.

Gas Detectors: Safeguarding Workplace Safety

Gas detectors are vital for ensuring a safe working environment by monitoring the presence of hazardous gases. Regular maintenance and calibration ensure that these detectors function effectively, providing timely alerts in case of gas leaks.

Calibration Steps:

1. Use a known concentration of gas for calibration testing.

2. Adjust the sensitivity settings as required.

3. Document all calibration activities for compliance.

Maintenance Steps:

1. Inspect the detector for physical damage or corrosion.

2. Replace sensor cartridges as per the manufacturer’s recommendations.

3. Test functionality regularly through simulated gas exposure.

Pressure Transmitters: Accurate Pressure Monitoring

Pressure transmitters provide accurate and real-time pressure measurements essential for various industrial processes. Proper calibration and maintenance extend their operational life and improve reliability.

Calibration Steps:

1. Apply known pressure values and compare output.

2. Adjust the output signal to match the pressure applied.

3. Verify accuracy across the entire measurement range.

Maintenance Steps:

1. Inspect seals and connections for leaks.

2. Clean impulse lines to prevent blockage.

3. Perform visual checks for physical damage or wear.

Level Transmitters: Precision and Reliability in Measurement

Level transmitters are essential for monitoring fluid levels in tanks and silos. Ensuring ongoing accuracy through regular calibration and maintenance is paramount for avoiding overflows or shortages.

Calibration Steps:

1. Use known reference levels for calibration checks.

2. Adjust the transmitter settings as necessary.

3. Ensure that the output signal corresponds with the actual fluid levels.

Maintenance Steps:

1. Regularly clean and inspect the sensors for fouling.

2. Test for correct alignment and secure mounting.

3. Document all maintenance interventions for future reference.

Temperature Transmitters: Ensuring Process Integrity

Temperature transmitters are critical for maintaining process control by monitoring temperature variations accurately. Consistent calibration and maintenance are vital for operational reliability and compliance with safety standards.

Calibration Steps:

1. Use precision temperature references for calibration.

2. Adjust settings to ensure linearity across the measurement range.

3. Check for hysteresis to confirm performance stability.

Maintenance Steps:

1. Inspect physical conditions of the sensor head and connections.

2. Clean sensors periodically to eliminate interference.

3. Conduct functional tests to ensure output accuracy.

Flow Transmitters: Efficiency in Fluid Management

Flow transmitters are crucial for measuring flow rates in industrial applications. Keeping them calibrated and well-maintained ensures optimal performance and accuracy.

Calibration Steps:

1. Standardise flow conditions for calibration benchmarks.

2. Adjust output to align with flow rate measurements.

3. Verify calibration with tracked flow standards.

Maintenance Steps:

1. Regularly inspect and clean the measuring element.

2. Replace worn or damaged seals and internal components.

3. Review and test for software updates frequently.

Nuclear Flux Transmitters: Safety in Critical Applications

Nuclear flux transmitters are critical for monitoring radiation levels in nuclear facilities. Proper calibration and stringent maintenance practices are essential to ensure safety and compliance with regulatory standards.

Calibration Steps:

1. Use certified radiation sources for calibration checks.

2. Adjust settings based on facility-specific guidelines.

3. Validate accuracy across operational ranges regularly.

Maintenance Steps:

1. Conduct comprehensive checks of electronic components.

2. Inspect shielding and protective casing for integrity.

3. Maintain an updated log of all maintenance activities for oversight.

By adhering to these calibration and maintenance procedures, industries can ensure that their critical instrumentation and sensors operate efficiently, ensuring safety and compliance while maintaining high-quality outputs.

Discover more from Tamfis Nigeria Lmited

Subscribe to get the latest posts sent to your email.

Hot Deals

Hot Deals Shopfinish

Shopfinish Shop

Shop Appliances

Appliances Babies & Kids

Babies & Kids Best Selling

Best Selling Books

Books Consumer Electronics

Consumer Electronics Furniture

Furniture Home & Kitchen

Home & Kitchen Jewelry

Jewelry Luxury & Beauty

Luxury & Beauty Shoes

Shoes Training & Certifications

Training & Certifications Wears & Clothings

Wears & Clothings