Blog

Module 1: Instrumentation Fundamentals & Calibration

Universal Foundation for Safety, Quality & Compliance

1. SI Units: The Language of Measurement

Core Concept: Standardised units ensure consistency across industries.

Key Units:

- Pressure: Pascal (Pa), bar, psi

- Temperature: Kelvin (K), Celsius (°C), Fahrenheit (°F)

- Flow: m³/s, L/min, GPM

- Level: Meters (m), % of span

Industry Application:

- Nuclear: Precise Kelvin for reactor cooling.

- Oil & Gas: PSI/bar for pipeline pressure.

- Power: °C/°F for turbine exhaust monitoring.

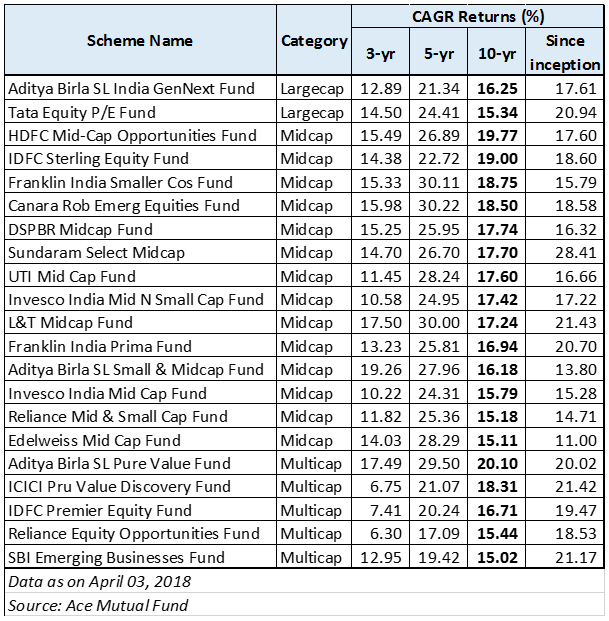

Table: SI Unit Conversions

| Parameter | SI Unit | Industrial Equivalent |

|---|---|---|

| Pressure | 1 Pa | 0.00001 bar |

| Temperature | 0 K | -273.15°C |

| Flow | 1 m³/s | 15,850 GPM |

Visual:

- Animation: Global map showing SI units used in target industries (e.g., PSI in US pipelines, bar in EU refineries).

2. Accuracy, Precision & Errors

Definitions:

- Accuracy: Closeness to the true value.

- Precision: Repeatability of measurements.

- Error: Deviation from true value (e.g., ±0.5% FS).

Industry Impact:

- Safety: Inaccurate pressure readings ⇒ overpressure explosions.

- Quality: Imprecise temperature control ⇒ product defects.

Diagram: Accuracy vs. Precision

Caption: High accuracy + low precision = Consistent errors. High precision + low accuracy = Repeatable but wrong.

Visual:

- GIF: Dartboard analogy (accurate = bullseye, precise = tight cluster).

3. Range, Span & Linearity

Terminology:

- Range: Min/Max measurable values (e.g., -50°C to 150°C).

- Span: Difference between upper/lower limits (e.g., 200°C).

- Linearity: Output deviation from a straight line.

Table: Calibration Range Examples

| Instrument | Range | Span | Application |

|---|---|---|---|

| Pressure Transmitter | 0-600 psi | 600 psi | Hydraulic systems (Mfg) |

| RTD Sensor | -200°C to 500°C | 700°C | Reactor core (Nuclear) |

Visual:

- Graph: Linearity curve showing ideal vs. actual output.

4. Hysteresis & Deadband

Critical Concepts:

- Hysteresis: Output variation when input reverses direction (e.g., mechanical friction in valves).

- Deadband: Input range with no output change (e.g., stuck valve stem).

Industry Risks:

- Deadband in safety valves ⇒ Delayed shutdown in oil/gas emergencies.

- Hysteresis in nuclear control rods ⇒ Reactor instability.

Diagram: Hysteresis Loop

Caption: Hysteresis loop showing output lag during increasing/decreasing input.

Visual:

- Animation: Valve stem moving with/without hysteresis (contrast smooth vs. jerky motion).

5. Hands-On Calibration Procedures

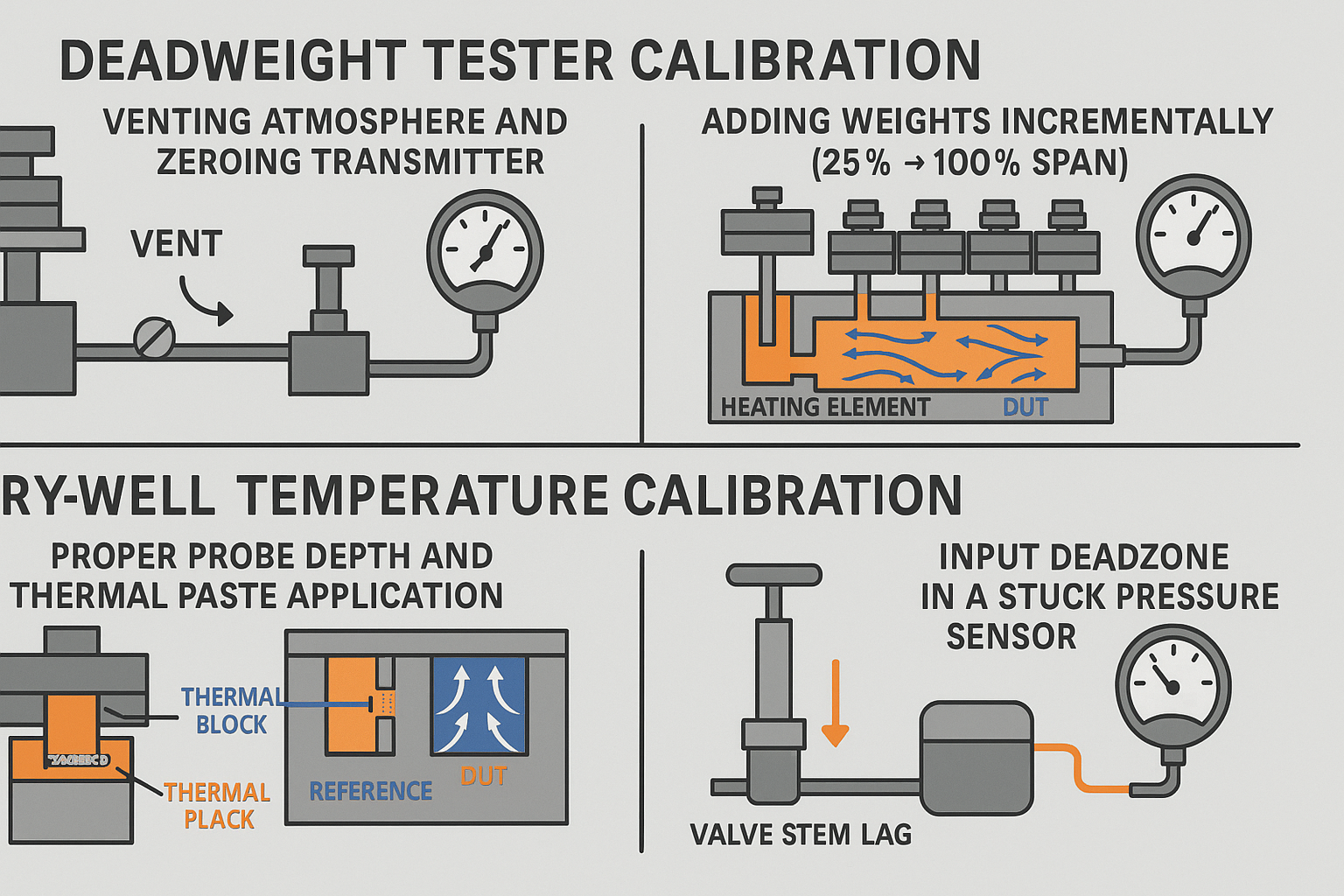

A. Pressure Calibration (Deadweight Tester)

Equipment:

- Deadweight tester (primary standard)

- Test gauge/transmitter

Step-by-Step:

- Zero Adjustment: Vent to atmosphere; set output to 0 psi.

- Apply Weights: Add calibrated masses (e.g., 100 psi = 100 lb on 1 in² piston).

- Record Output: Note gauge reading at 0%, 25%, 50%, 75%, 100% of span.

- Calculate Error:

Error = (Observed Value - Expected Value) / Span × 100. - Adjust Span/Zero: Trim potentiometers until error ≤ tolerance.

Safety Tip: Always wear PPE when handling high-pressure systems.

Visuals:

- Cross-Section: Deadweight tester internals (piston, weights, hydraulic fluid).

- GIF: Step-by-step weight loading sequence.

B. Temperature Calibration (Dry-Well)

Equipment:

- Dry-well calibrator (portable heat source)

- Reference RTD/thermocouple

- Device Under Test (DUT)

Step-by-Step:

- Insert Probes: Place DUT and reference sensor in dry-well wells.

- Setpoints: Test 0°C, 50°C, 100°C, 150°C (cover instrument range).

- Stabilize: Wait 15 mins per setpoint; record DUT vs. reference.

- As-Found Data: Document errors before adjustment.

- Trim DUT: Adjust zero/span via HART communicator or onboard buttons.

Industry Tip: In nuclear plants, use rad-hardened dry-wells near reactors.

Visuals:

- Animation: Heat flow path in dry-well (heater → block → sensors).

- GIF: Probe insertion best practices (depth, thermal paste application).

6. Industry-Specific Calibration Protocols

| Industry | Standard | Critical Instruments | Tolerance |

|---|---|---|---|

| Oil & Gas | API 570 | Pressure Safety Valves | ±1% FS |

| Nuclear | IEEE 344 | Reactor Coolant Temp Sensors | ±0.25% FS |

| Power | ASME B31.1 | Steam Flow Meters | ±0.5% FS |

| Manufacturing | ISO 9001 | Batch Reactor Controllers | ±1% FS |

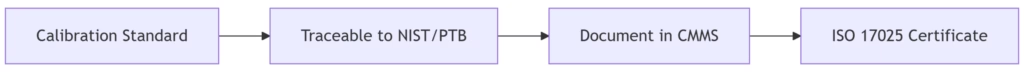

Compliance Workflow

7. Summary: Key Takeaways

- Safety: Calibration prevents catastrophic failures (e.g., overpressure explosions).

- Quality: SI units + accuracy = product consistency.

- Compliance: Documentation satisfies ISO 9001, API, ASME.

- Tools: Deadweight testers (pressure) and dry-wells (temp) are field-proven.

Final Visual:

- Infographic: Calibration impact across industries:

- Oil/Gas: Prevents spills.

- Nuclear: Avoids meltdowns.

- Power: Ensures grid stability.

Next Module: [Pressure Measurement Techniques]

Feedback Loop: Submit calibration logs at [Tamfitronics.com/portal]

Visual Assets Package:

*© 2025 Tamfitronics. Complies with ISA 84, IEC 61511, and ANSI/NCSL Z540-1.