Blog

Advanced Topics in Instrumentation

Instrumentation engineering has evolved significantly with advancements in electronics, digital technologies, control theory, and artificial intelligence. Modern instrumentation systems are sophisticated assemblies of sensors, signal processing circuits, control algorithms, and computational tools that collectively measure, monitor, control, and predict systems behaviour with high precision and reliability. This comprehensive article explores advanced concepts in instrumentation, specifically focusing on signal processing, real-time control, AI integration, and predictive maintenance.

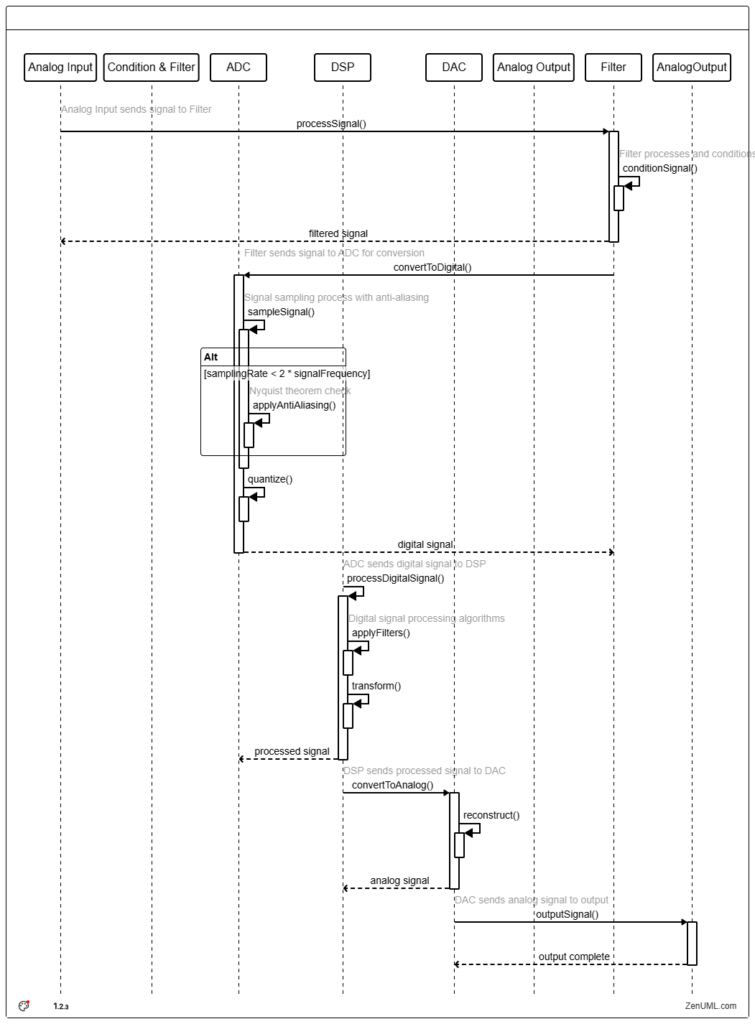

1. Signal Processing in Digital Instruments

Signal processing is fundamental to the operation of digital instruments, particularly in improving accuracy, reliability, and information extraction capabilities. With increasing demand for precision, digital instruments leverage sophisticated algorithms to handle noisy, distorted, or incomplete data gathered from sensors. Advanced signal processing techniques enable instrumental measurements to achieve unprecedented levels of sensitivity and specificity.

Key Techniques

- Filtering Techniques (Digital filters): To remove noise and unwanted frequency components, filters like finite impulse response (FIR) and infinite impulse response (IIR) are used.

- Fast Fourier Transform (FFT): Converts time-domain data into frequency domain to analyze signal characteristics, identifying dominant frequencies or harmonics.

- Wavelet Transform: Helps extract time and frequency information simultaneously, ideal for transient event detection in signals.

- Adaptive filtering: Filters capable of adjusting their parameters dynamically in response to changing signal conditions, essential in environments with variable noise.

Applications and Use-Cases

- Biomedical Instrumentation: ECG and EEG signal conditioning, noise reduction, real-time diagnostics.

- Communications: Signal modulation/demodulation, noise mitigation in wireless transmission.

- Industrial Process Measurement: Improvement in accuracy of instruments like flow meters, pressure and temperature sensors by noise reduction and signal conditioning.

Future Directions

Emerging techniques in deep learning-based signal processing are leading to even more effective extraction and interpretation of signals, facilitating innovation in instrumentation capabilities.

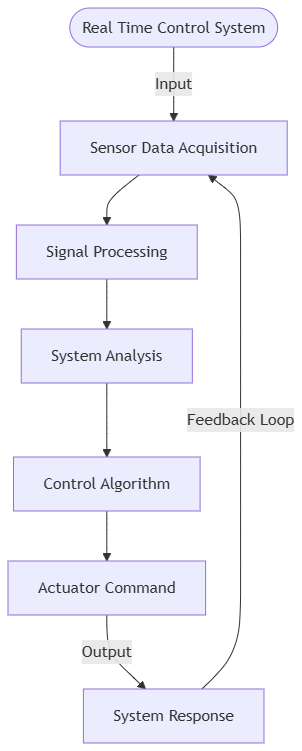

2. Real-Time Control Systems

Real-time control systems are integral to modern instrumentation engineering, enabling immediate system responses based upon real-time sensor data acquired during ongoing processes. The robustness, speed, and predictability of these systems significantly impact productivity and safety in automated and interconnected environments.

Core Principles of Real-Time Control Systems

- Determinism: Maintaining strict response times in processing and execution.

- Low Latency: Minimizing delay between measurement and actuation.

- Reliability: Ensuring continual operation under predefined specifications without system degradation.

- Predictability: Clear understanding and control over system processes and outcome timings.

Key Technologies and Frameworks in Real-Time Control

- RTOS (Real-Time Operating Systems): Platforms such as FreeRTOS, RTLinux, and QNX provide deterministic resource scheduling critical for real-time control application performance.

- Field-Programmable Gate Arrays (FPGAs): Used for implementation of high-speed parallel processing systems, allowing advanced real-time control algorithms to execute quickly and deterministically.

- Programmable Logic Controllers (PLCs): Reliable controllers predominantly used in industrial applications to implement complex logical operations and control strategies reliably.

Application Examples

- Automotive Systems: Anti-lock braking systems (ABS), airbag deployment, engine control units.

- Industrial Automation: Manufacturing process control, robotics coordination.

- Robotics: Precision position control, autonomous navigation and task execution.

Future Developments

Developments such as advanced multi-core processors optimally designed for determinism, increased feasibility of cloud-based real-time control platforms, and integration with artificial intelligence will continue to redefine the landscape of real-time control in instrumentation.

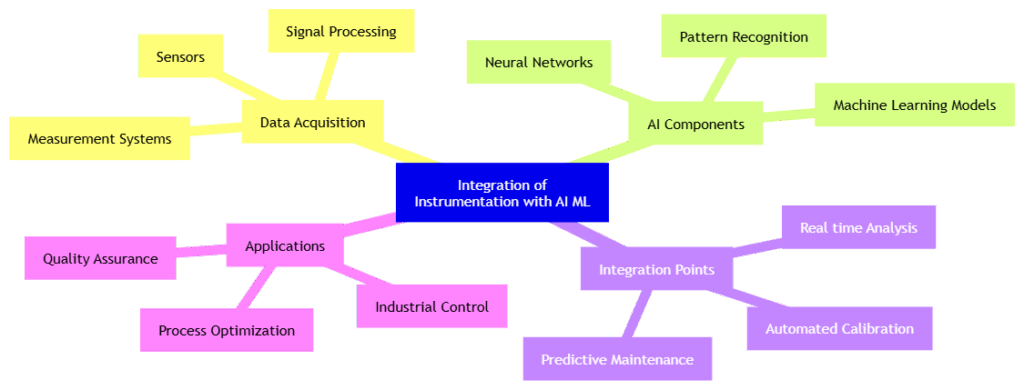

3. Integration of Instrumentation with AI and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) significantly enhance instrumentation systems, allowing for intelligent decision-making, data analysis, predictive capabilities, and autonomous system control. As instrumentation gathers ever greater volumes of data, AI integration helps to extract actionable insights from the abundance of available information.

Importance of AI Integration

- Enhanced Measurement Accuracy: AI can dynamically calibrate signals and correct errors based on historical and real-time inputs.

- Autonomous Systems: AI-driven sensing and decision-making can lead to the evolution of fully autonomous intelligent instrumentation systems.

- Adaptive Control: AI algorithms enable systems to adapt capabilities dynamically, adjusting operational parameters based on evolving circumstances and data.

Common AI Techniques Used in Instrumentation

- Neural Networks: Used to model nonlinear relationships between measured signals and desired outputs.

- Machine Vision: Cameras coupled with image processing AI improve inspection accuracy and reduce deterioration risk.

- Reinforcement Learning: Systems learn control algorithms through continuous interaction with their environment.

- Predictive Analytics: ML methods analyse historical data to visualise future system states, enabling proactive control measures.

Applications in Instrumentation

- Quality Control: AI-driven vision systems automatically inspect product quality with high accuracy.

- Energy Efficiency in Processes: Optimise operational parameters in industrial processes to consume minimal energy without compromising product quality.

- Autonomous Vehicle Instrumentation: Real-time environment sensing and interpretation, collision avoidance, intelligent navigation.

Future Prospects

Fully autonomous AI-integrated devices, edge computing paradigms for embedded instrumentation, and real-time analytics at sensor level are key futuristic trends in instrumentation.

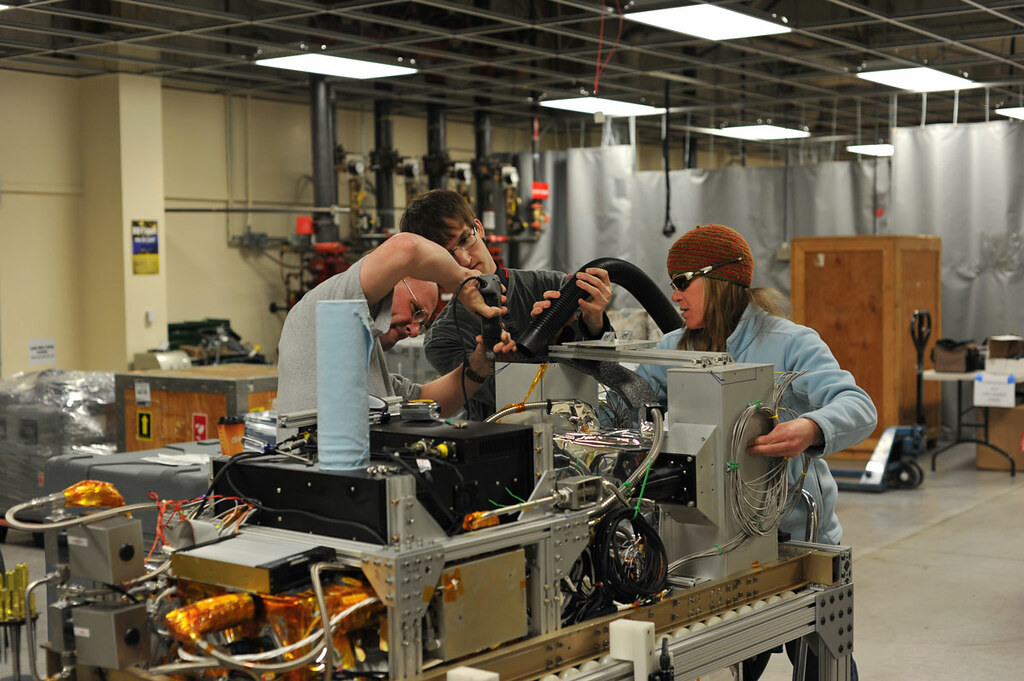

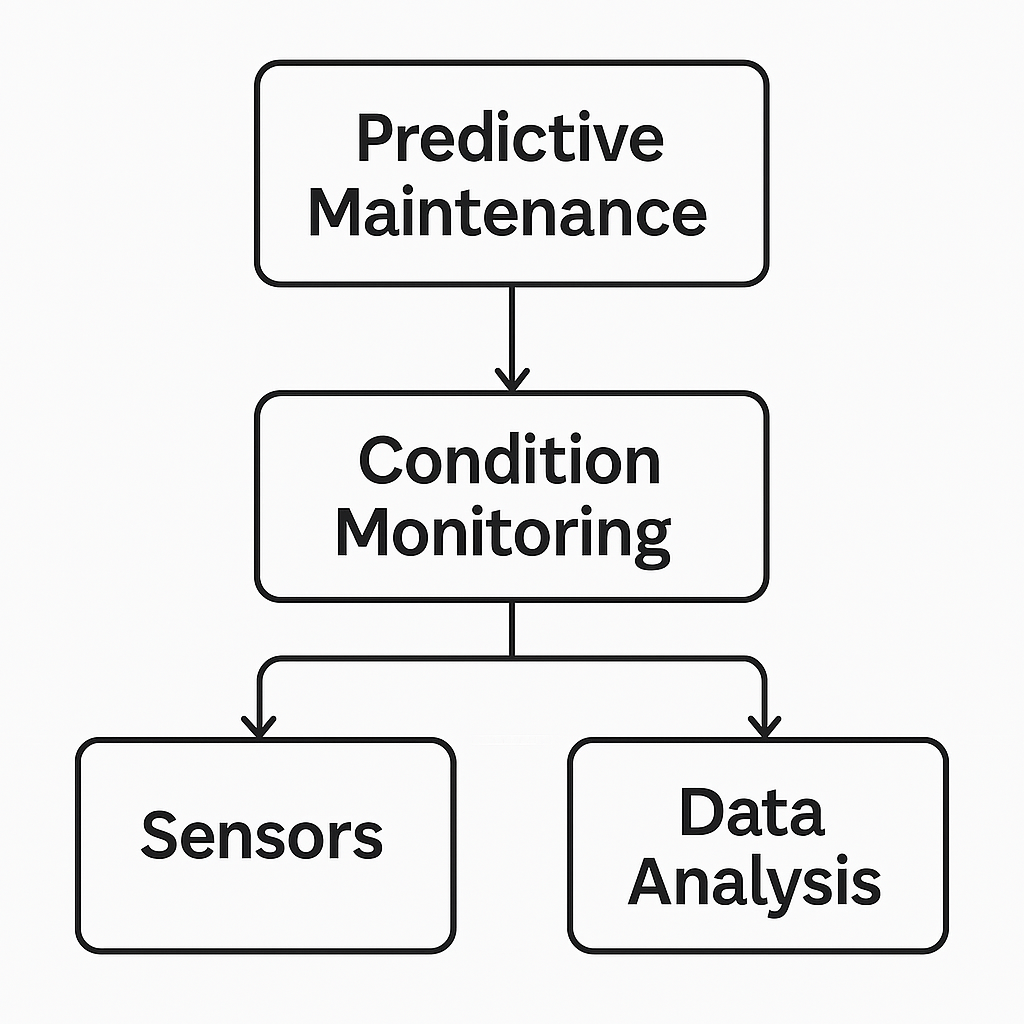

4. Predictive Maintenance and Condition Monitoring

Predictive maintenance and condition monitoring aim to avoid machine downtime, unnecessary maintenance, and unexpected failures by evaluating real-time operational data and using advanced analytical techniques. Effective predictive maintenance significantly reduces operational costs, enhances equipment lifespan, and improves safety.

Key Components of Predictive Maintenance Systems

- Sensors and data acquisition: Sensors for pressure, temperature, vibration, and acoustic emissions to capture health status in real-time.

- Data-enabled diagnostics: Condition monitoring using advanced signal analysis using FFT, wavelets, or AI-based diagnostics.

- Prognostics: Predicting equipment lifespan utilising predictive analytics like ML models on collected data histories.

- Maintenance scheduler: Decision support for optimal maintenance timing reducing downtime and expense.

Common Predictive Analytical Techniques

- Regression Analysis: Forecast future trends, forecasting failure states and remaining-life deployments.

- Classification Techniques: Categorising equipment status into varying operational or failure modes.

- Anomaly Detection: Identifying early-stage faults before severe issues manifest themselves.

Applications & Benefits

- Industrial Machinery: Prevention of unplanned downtime in manufacturing and production line equipment.

- Aerospace and Automotive: Real-time monitoring of engines, bearings, and critical components, ensuring safety.

- Energy Production: Monitoring turbines and pumps for optimised performance and longevity.

Future Outlook

In the future, predictive maintenance will likely evolve towards increased intelligence and automation, adaptive maintenance planning, and holistic integration with broader Industry 4.0 strategies.

Ultimately, advancements in instrumentation technology encompassing these advanced topics will profoundly improve human-machine interactions, system autonomy, and operational excellence across diverse domains.