MODULE 5: Level Measurement (Liquids, Solids, Interfaces)

Introduction

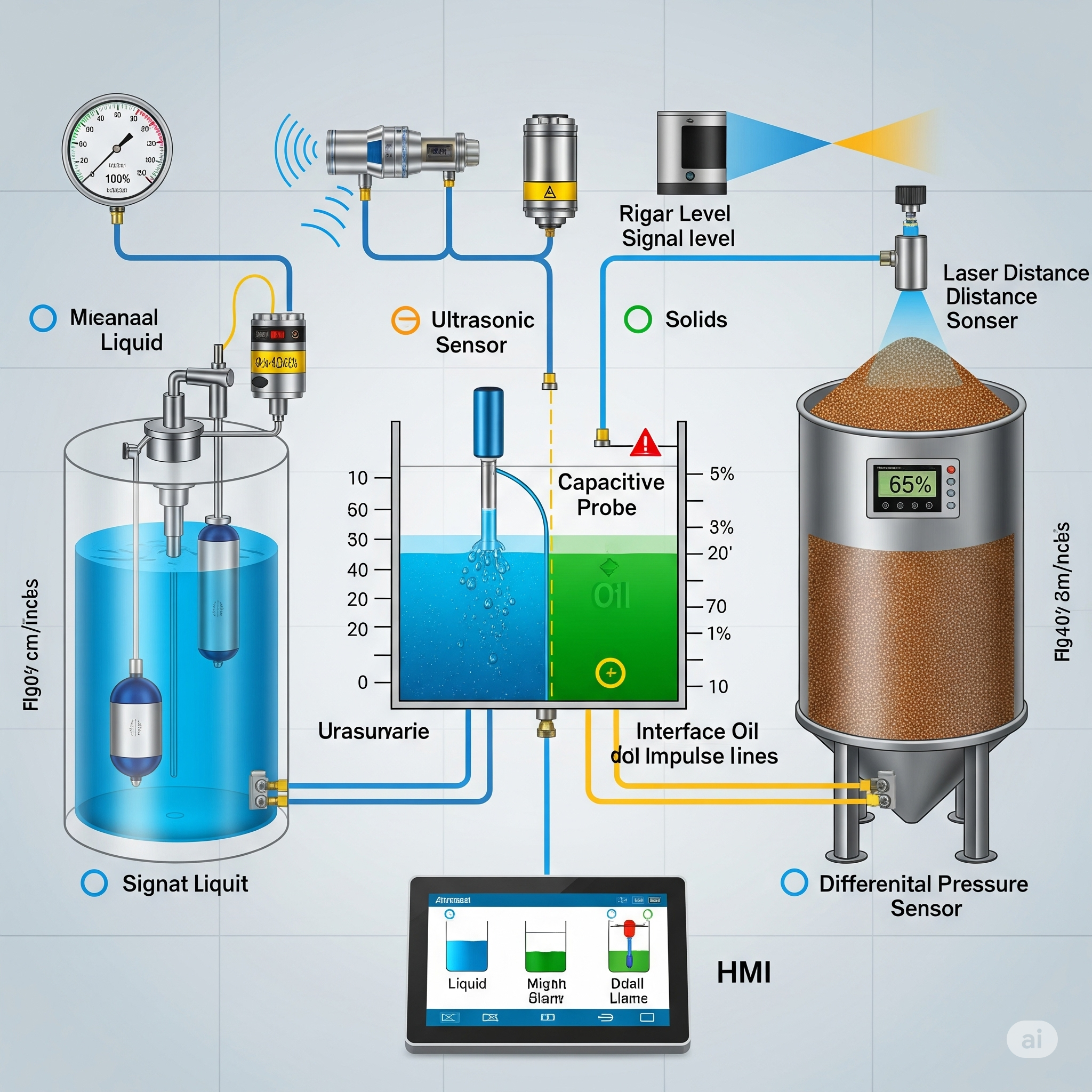

Level measurement plays a crucial role in ensuring the safe and efficient operation of industrial processes. From storage tanks in oil depots to chemical reactors and nuclear containment vessels, accurate and reliable level detection ensures effective inventory management, process control, and safety compliance.

This module provides a comprehensive overview of the technologies used for level measurement, including contact and non-contact methods, challenges faced in real-world applications, and the criteria for choosing the right instrument. Focus areas include tank farms, silos, separators, and reactor vessels across industries like oil & gas, manufacturing, energy, and nuclear power.

Section 1: Principles of Level Measurement

1.1 Differential Pressure (DP) Measurement

Operating Principle: Level is inferred from the hydrostatic pressure exerted by the height of the liquid. A DP transmitter with one port at the bottom and one at the reference point measures the pressure difference.

Best For:

- Pressurised tanks

- Liquids with consistent density

Visuals:

- Diagram of DP cell setup with impulse lines and condensate pots.

1.2 Radar Level Measurement

Two types are commonly used:

- FMCW (Frequency-Modulated Continuous Wave)

- Pulse Radar

Operating Principle: A microwave signal is emitted towards the surface. The time taken for the signal to reflect back determines the level.

Advantages:

- Immune to temperature, pressure, and vapours

- Works in extreme process conditions

Applications:

- Tank farms in oil & gas

- Reactors in chemical and nuclear sectors

Visuals:

- Animation showing radar wave propagation and reflection.

1.3 Ultrasonic Level Measurement

Operating Principle: High-frequency sound waves are emitted towards the surface. The echo time is used to calculate the distance to the fluid surface.

Advantages:

- Cost-effective

- Suitable for open tanks and solids

Challenges:

- Affected by foam, vapour, and dust

Applications:

- Silo and bin level in cement or grain industries

- Water treatment plants

Visuals:

- Diagram showing ultrasonic wave reflection in different environments.

1.4 Guided Wave Radar (GWR)

Operating Principle: Microwaves travel along a probe (rod or cable) and reflect back from the surface. Time-of-flight determines level.

Advantages:

- Better performance in vapour, foam, or turbulent conditions

- Suitable for interface level detection

Applications:

- Interface levels in oil-water separators

- Reactors with multiple phase layers

Visuals:

- Animation showing guided wave radar signal path along a rod.

1.5 Capacitance Level Sensors

Operating Principle: The dielectric constant between the probe and tank wall changes with level, altering the capacitance.

Advantages:

- Works with liquids and solids

- Can detect interface levels

Challenges:

- Requires calibration for each fluid

- Sensitive to coating build-up

Applications:

- Interface detection in oil separators

- Powder level in hoppers

1.6 Displacer Level Measurement

Operating Principle: A displacer suspended in a fluid experiences buoyancy force. This force is translated into level through a torque tube or transmitter.

Best For:

- Interface levels

- Conditions requiring mechanical simplicity

Challenges:

- Prone to wear and drift

- Not suitable for rapid level changes

Visuals:

- Diagram of torque tube mechanism and displacer float.

1.7 Nuclear Level Measurement

Operating Principle: A radioactive source emits gamma rays through the tank. The intensity reaching the detector changes with the level.

Advantages:

- Ideal for harsh or corrosive environments

- Non-intrusive

Challenges:

- Requires radiation safety protocols

- Higher cost and regulation compliance

Applications:

- Reactor vessels

- Bitumen or sludge tanks

Visuals:

- Animation of gamma ray interaction through tank walls and varying absorption.

Section 2: Common Measurement Challenges

| Challenge | Affected Technologies | Mitigation |

|---|---|---|

| Foam | Ultrasonic, Radar | Use GWR or radar with foam compensation |

| Vapours | Ultrasonic | Use radar or DP |

| Turbulence | Displacer, Ultrasonic | Use GWR or averaging techniques |

| Solids with dust | Ultrasonic | Use radar or GWR |

| Coating Build-up | Capacitance | Periodic cleaning, GWR alternative |

Section 3: Instrument Selection Criteria

- Fluid or Material Type: Liquid, slurry, solid, or multi-phase?

- Process Conditions: Pressure, temperature, corrosiveness

- Mounting Options: Top, bottom, side; accessibility

- Measurement Range: Tank height or silo depth

- Required Accuracy: Inventory vs. control application

- Safety and Compliance: Is radiation use permitted on-site?

Industry Tip: Use radar or GWR for volatile hydrocarbons. Use nuclear or GWR in high-pressure, high-temperature environments.

Section 4: Industry-Specific Applications

4.1 Oil & Gas: Tank Farms – Radar Level Measurement

Radar technology ensures high accuracy in measuring hydrocarbon levels in large tanks. FMCW radar is preferred for its higher resolution.

System Features:

- Antenna with purge system

- Temperature and pressure compensation

4.2 Nuclear Power: Reactor Vessel – Diverse Instrumentation

Level measurement in nuclear reactors requires redundancy. Combination of DP, GWR, and nuclear devices ensures continuous monitoring.

Setup:

- Multiple independent sensors

- Redundant signal processing

4.3 Manufacturing/Energy: Silo and Bin Level – Ultrasonic/GWR

Monitoring solid levels in silos can be challenging. Ultrasonic works for general bulk solids, while GWR provides accuracy in dusty environments.

Setup:

- Dust-immune GWR probe

- Echo-mapping calibration

4.4 Oil & Gas: Separator Interface – Capacitance/Displacer

Two or more immiscible fluids must be separated efficiently. Capacitance and displacer technologies enable accurate interface monitoring.

Use Case:

- Oil-water separation in upstream production

- Sludge-liquid level in wastewater plants

Conclusion

Level measurement is an essential aspect of process control across multiple industries. From traditional mechanical displacers to advanced radar and nuclear technologies, the choice of instrument depends on the application’s unique challenges and goals. Accurate level data supports operational safety, process efficiency, and compliance with regulatory standards.

Key Takeaways:

- Understand the strengths and weaknesses of each level measurement method

- Consider environmental and fluid conditions during selection

- Regular maintenance and calibration ensure long-term performance

Interactive Elements to Include:

Animated Videos

- Radar wave propagation animation

- Guided wave radar rod interaction

- Nuclear measurement gamma beam path

Image Gallery

- Tank farm radar setups

- Displacer level transmitter assembly

- Silo and separator instrument installation

Quiz Questions

- Match level technology to its application environment

- Identify errors in DP and radar installations

- Calculate hydrostatic pressure for DP measurement

References:

- IEC 61298-2 Industrial-process control documentation standards

- ISA Level Measurement Best Practices

- Rosemount, Siemens, VEGA, and Endress+Hauser Application Notes

End of Module 5 – Tamfitronics.com Training Series