Blog

Module 2: Pressure Measurement (All Media & Environments)

Objective: This module provides a thorough understanding of pressure measurement principles, sensor technologies, and the best practices for installation and maintenance required for ensuring safety, quality, and efficiency in industrial processes.

1. Core Principles of Pressure Sensing

Pressure is one of the most critical process variables. Understanding how we convert a physical force into an electronic signal is fundamental.

1.1. Strain Gauge Principle

- How It Works: This is the most common technology. It relies on the principle of piezoresistance. A fine wire grid (the strain gauge) is bonded to a diaphragm. When process pressure flexes the diaphragm, the wires are stretched, which increases their electrical resistance. This change in resistance is precisely measured and converted into a pressure reading.

- Best For: General purpose applications. They are robust, reliable, and offer a great price-to-performance ratio.

- Visual Aid: An animation would show a diaphragm flexing under pressure. As it flexes, the bonded strain gauge stretches, and a connected ohmmeter shows the resistance increasing.

1.2. Capacitive Principle

- How It Works: A capacitive sensor uses two conductive plates to form a capacitor. One plate is a fixed diaphragm, while the other is the sensing diaphragm that moves with process pressure. As pressure changes, the distance between the plates changes, which in turn changes the capacitance. This capacitance is measured and correlated to the pressure.

- Best For: Low-pressure applications, and environments requiring high accuracy and overpressure protection.

- Visual Aid: An animation showing two capacitor plates. As pressure increases, the sensing plate moves closer to the fixed plate, and a connected capacitance meter shows the value increasing.

1.3. Piezoelectric Principle

- How It Works: Certain materials, like quartz crystals, generate a small electrical voltage when they are mechanically compressed. This is the piezoelectric effect. The sensor uses a crystal that is in contact with the process pressure. The voltage generated is directly proportional to the pressure applied.

- Best For: Measuring dynamic or rapidly changing pressures (e.g., explosions, pulsations, engine combustion). They are not suitable for static pressure measurement.

- Visual Aid: A short animation showing a crystal being squeezed by a piston. As it’s compressed, a voltmeter connected to it shows a voltage spike.

1.4. Resonant Frequency Principle

- How It Works: A wire is held under tension in a magnetic field. An oscillator circuit causes the wire to vibrate at its natural resonant frequency. Process pressure is applied to a diaphragm connected to this wire. As pressure changes, the tension on the wire changes, which alters its resonant frequency. This frequency is measured with extreme accuracy.

- Best For: Applications demanding the highest accuracy and long-term stability, such as custody transfer and calibration standards.

2. Sensor Types: Gauge, Absolute, and Differential

The type of sensor you choose depends on the reference pressure you are measuring against.

2.1. Gauge Pressure (psig, barg)

- Measures: Process pressure relative to the local atmospheric (barometric) pressure. The sensor is vented to the atmosphere.

- Use Case: This is the most common measurement. For example, if you measure tire pressure at 32 psig, it’s 32 PSI above the current atmospheric pressure.

- Visual Aid: A simple diagram showing a pressure sensor with one connection to the process and a small vent on the opposing side of the diaphragm open to the air.

2.2. Absolute Pressure (psia, bara)

- Measures: Process pressure relative to a perfect vacuum (zero pressure). The reference side of the diaphragm is sealed with a vacuum.

- Use Case: When you need a measurement unaffected by changes in atmospheric pressure. Essential for vacuum applications or calculating the density of gases.

- Visual Aid: A diagram similar to the gauge sensor, but the reference side is shown as a sealed, evacuated chamber.

2.3. Differential Pressure (DP or ΔP)

- Measures: The difference between two separate pressure points (P1 – P2). The sensor has two process connections: a “High” side and a “Low” side.

- Use Case: Extremely versatile. Used for:

- Flow Measurement: Measuring pressure drop across an orifice plate.

- Level Measurement: Measuring the hydrostatic head pressure of a liquid in a tank.

- Filter Monitoring: Measuring pressure drop across a filter to see if it’s clogged.

- Visual Aid: Animation showing a DP transmitter connected across a filter in a pipe. As the filter gets clogged, the pressure on the “High” side increases relative to the “Low” side, and the DP reading goes up.

3. Installation Best Practices: Getting it Right

A perfect sensor installed incorrectly will always give a bad reading.

3.1. Pressure Tap Location is Critical

- For Gases & Steam: Install the tap on the TOP or SIDE of the pipe. This prevents condensate (liquid) from collecting in the impulse lines and creating a false pressure head.

- For Liquids: Install the tap on the SIDE or BOTTOM of the pipe. This ensures the line is always filled with liquid and prevents trapped gas/air bubbles from causing errors.

- Visual Aid: A clear “Do this / Don’t do that” diagram showing correct and incorrect tap locations for both liquid and gas service on a horizontal pipe.

3.2. Impulse Lines & Valve Manifolds

- Impulse Lines: The tubing connecting the process tap to the sensor.

- Valve Manifolds: A 3-valve or 5-valve manifold is essential for maintenance. It allows a technician to safely:

- Isolate the sensor from the process.

- Bleed trapped pressure.

- Equalize the high and low sides (for DP sensors) for a zero check.

- Calibrate the sensor without shutting down the process.

3.3. Diaphragm Seals: Protecting Your Sensor

- What they are: A diaphragm seal is a barrier that isolates the sensor from the process fluid. The pressure is transferred from the process through a flexible diaphragm and a stable fill fluid to the sensor itself.

- When to use them:

- The process fluid is corrosive, viscous, or contains solids.

- The process is at an extreme temperature (hot or cold).

- The process is sanitary (food, pharma).

- Visual Aid: A step-by-step diagram showing the components: Sensor -> Capillary Tube (optional) -> Fill Fluid -> Diaphragm Seal Body -> Diaphragm in contact with the process. Highlight different seal types like flanged, threaded, and sanitary.

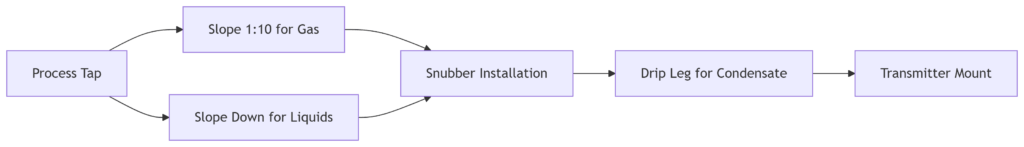

3.4. Handling Pulsation: Snubbers

- Problem: Rapid pressure spikes from pumps or valves can damage sensitive sensor internals.

- Solution: A snubber (or pulsation dampener) is a simple device installed before the sensor. It has a porous metal disc or a piston that restricts the flow just enough to average out the pressure spikes, giving the sensor a stable reading.

- Visual Aid: A short animation showing a pressure gauge needle fluctuating wildly. A snubber is installed, and the needle becomes steady.

4. Industry Focus: Real-World Applications

| Industry | Application | Challenge | Solution & Rationale |

|---|---|---|---|

| Power | Boiler Drum Pressure | Extreme temperature and pressure steam. | Remote Seal Transmitter. A gauge or absolute sensor is connected via a capillary tube to a diaphragm seal. This keeps the sensitive electronics away from the heat. A “pigtail syphon” is used at the tap to create a condensate water barrier, protecting the diaphragm from direct steam contact. |

| Oil & Gas | Wellhead Pressure | Abrasive fluids (sand), high pressure, corrosive H₂S gas, vibration. | Robust Strain Gauge Sensor. A heavy-duty sensor with a diaphragm seal made of corrosion-resistant material like Inconel or Hastelloy C is required to withstand the harsh environment. |

| Nuclear | Reactor Coolant Pressure | Extreme safety and reliability needs, radiation, high consequence of failure. | Qualified Resonant or Capacitive Sensor. These sensors offer the highest reliability and are made with materials certified for nuclear service. Redundancy (multiple sensors for one process point) is mandatory. |

| Manufacturing | Process Vessel Pressure | Wide variety of chemicals, potential for vacuum and pressure, clogging. | Differential Pressure (DP) Transmitter. Often used for both level and pressure. Diaphragm seals are essential, with materials (e.g., Tantalum, PTFE lining) selected for chemical compatibility to prevent corrosion and ensure process purity. |