Blog

Instrumentation for Environmental and Process Monitoring

Gas Analyzers

Gas Analyzers

Gas analyzers are critical instruments used to determine the concentration of specific gases within a given sample, whether it’s ambient air, industrial emissions, or process streams. Their importance spans across environmental protection, industrial safety, process optimization, and quality control. Understanding the principles and applications of various gas analyzer technologies is fundamental for effective monitoring.

Importance of Gas Analysis:

- Environmental Monitoring: Detecting and quantifying pollutants such as carbon monoxide (CO), nitrogen oxides (NOx), sulfur dioxide (SO2), volatile organic compounds (VOCs), and particulate matter (PM) in the atmosphere to assess air quality and identify pollution sources.

- Industrial Safety: Monitoring workplace environments for hazardous gases like hydrogen sulfide (H2S), methane (CH4), ammonia (NH3), and flammable gases to prevent explosions, poisoning, and other safety incidents.

- Process Control: Analyzing gas compositions in industrial processes, such as combustion, chemical reactions, and fermentation, to optimize efficiency, yield, and product quality.

- Emissions Monitoring: Measuring greenhouse gases (e.g., CO2, CH4, N2O) and other pollutants released from industrial stacks, vehicles, and agricultural activities to ensure compliance with environmental regulations.

- Healthcare and Research: Analyzing respiratory gases, blood gases, and conducting research involving gaseous samples.

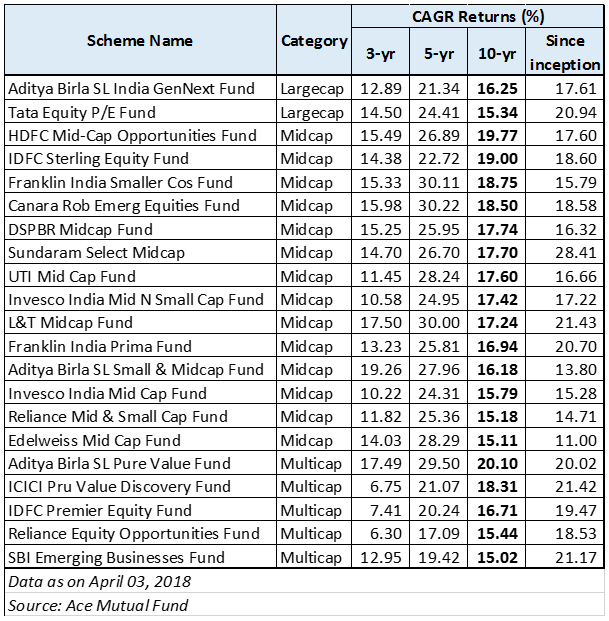

Types of Gas Analyzers:

Several technologies are employed in gas analyzers, each with its own principles of operation, sensitivity, selectivity, response time, and application suitability. Some common types include:

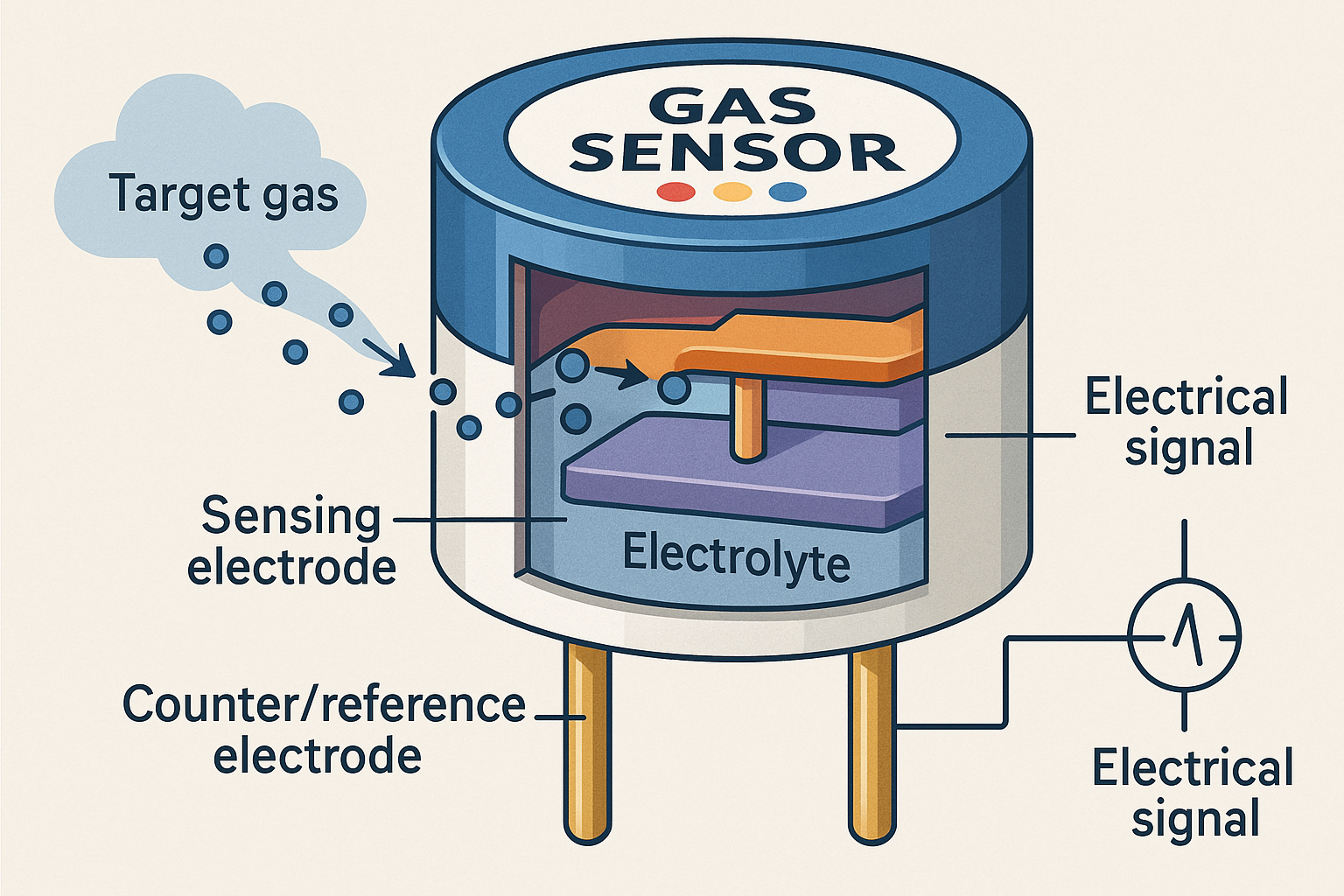

Electrochemical Sensors: These sensors work based on the electrochemical reaction between the target gas and a sensing electrode. The reaction produces an electrical signal (current or voltage) proportional to the gas concentration. Electrochemical sensors are often used for detecting gases like CO, H2S, O2, and specific toxic gases due to their relatively low cost, small size, and portability. However, they can be affected by humidity, temperature, and the presence of interfering gases.

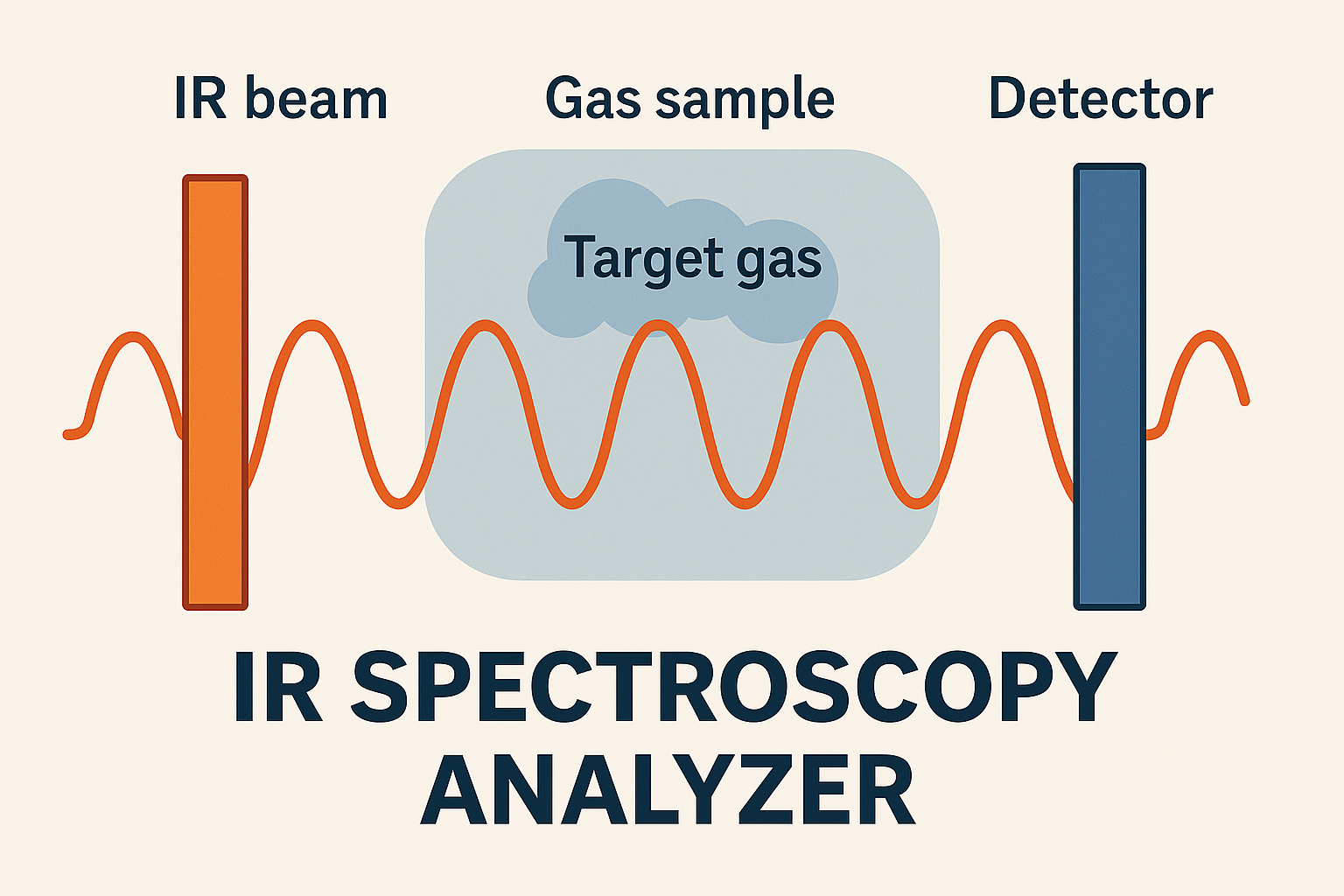

Infrared (IR) Spectroscopy Analyzers: These analyzers utilize the principle that many gases absorb infrared radiation at specific wavelengths. By passing an IR beam through a gas sample and measuring the amount of radiation absorbed at these characteristic wavelengths, the concentration of the target gas can be determined. Non-Dispersive Infrared (NDIR) spectroscopy is a common technique used for monitoring CO, CO2, and hydrocarbons. IR analyzers offer good sensitivity and selectivity but can be more expensive than electrochemical sensors

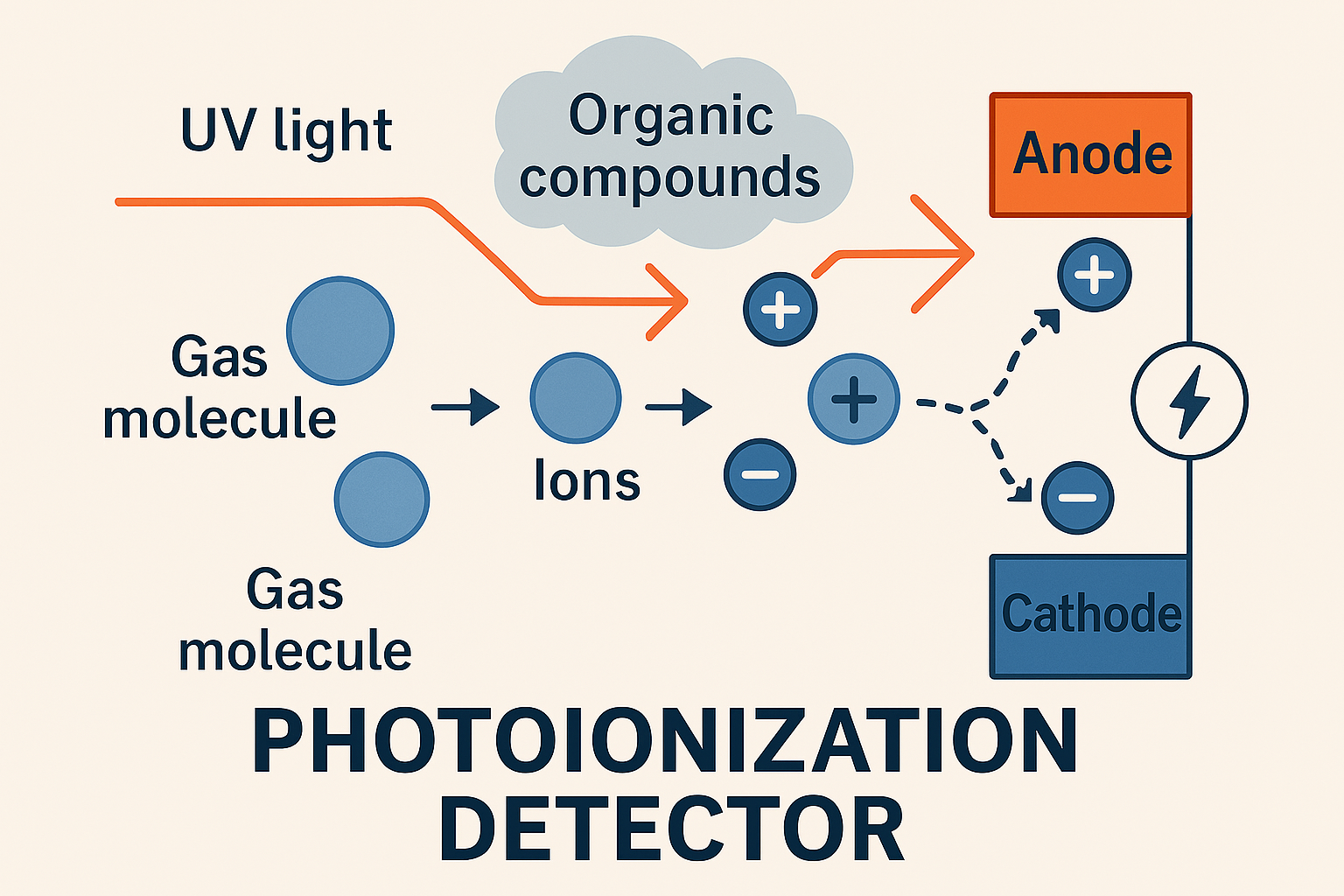

Photoionization Detectors (PIDs): PIDs use ultraviolet (UV) light to ionize gas molecules with ionization potentials lower than the energy of the UV lamp. The generated ions are then collected by electrodes, producing a current proportional to the concentration of the ionizable gases, such as VOCs. PIDs are known for their broad sensitivity to a wide range of organic compounds and are often used in environmental monitoring and industrial hygiene applications.

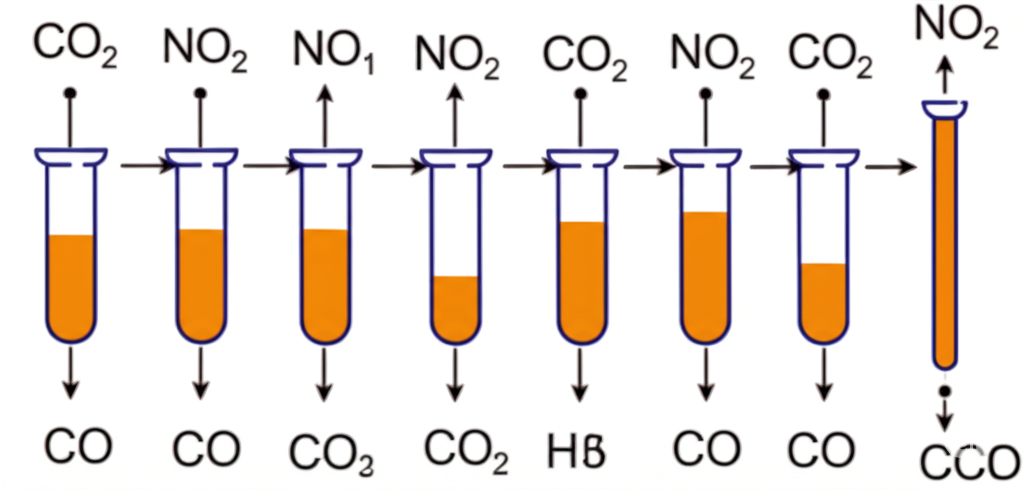

Gas Chromatography (GC): GC is a separation technique that separates different volatile compounds in a gaseous sample based on their boiling points and interaction with a stationary phase in a column. Once separated, the compounds are detected by various detectors, such as Flame Ionization Detectors (FIDs) for hydrocarbons, Thermal Conductivity Detectors (TCDs) for universal detection, and Electron Capture Detectors (ECDs) for halogenated compounds. GC provides excellent separation and identification capabilities but is generally more complex and requires skilled operators.

Mass Spectrometry (MS): MS is often coupled with GC (GC-MS) to provide detailed identification and quantification of gas components. Mass spectrometers ionize gas molecules and then separate these ions based on their mass-to-charge ratio. The resulting mass spectrum serves as a fingerprint for each compound, allowing for accurate identification even in complex mixtures. GC-MS is a powerful technique used in environmental analysis, forensic science, and research.

Optical Absorption Spectroscopy (e.g., UV-Vis, DOAS): Techniques like Differential Optical Absorption Spectroscopy (DOAS) measure the absorption of light at specific wavelengths by gaseous pollutants in the atmosphere. By analyzing the spectral features of the absorbed light, the concentration of various gases like NO2, SO2, O3, and formaldehyde can be determined over long path lengths. These methods are valuable for regional air quality monitoring.

Chemiluminescence Analyzers: These analyzers detect the light emitted when a target gas reacts with a specific chemical reagent. The intensity of the emitted light is proportional to the concentration of the gas. Chemiluminescence is commonly used for monitoring NOx and ozone (O3) in air quality monitoring stations.

Selection Criteria for Gas Analyzers:

Choosing the appropriate gas analyzer depends on several factors, including:

- Target Gas(es): The type of gas being monitored dictates the suitable sensor technology.

- Concentration Range: Different analyzers have varying detection limits and dynamic ranges.

- Accuracy and Precision Requirements: The application might demand high accuracy or simply trend monitoring.

- Selectivity: The ability to selectively measure the target gas without interference from other gases in the sample.

- Response Time: How quickly the analyzer can provide a reading after exposure to the gas.

- Environmental Conditions: Temperature, humidity, and pressure can affect the performance of some analyzers.

- Portability and Deployment: Whether the analyzer needs to be handheld, portable, or installed in a fixed location.

- Cost: Initial investment, maintenance, and operational costs.

Applications in Nigeria:

In Nigeria, gas analyzers play a crucial role in addressing various environmental and industrial challenges:

- Oil and Gas Industry: Monitoring for toxic gases (H2S, mercaptans) and flammable gases (methane, propane) in refineries, pipelines, and oil fields to ensure worker safety and prevent accidents. Emissions monitoring of flaring activities for compliance with environmental regulations.

- Power Generation: Analyzing flue gases from power plants to monitor NOx, SO2, and CO emissions. Optimizing combustion processes for efficiency and reduced pollution.

- Manufacturing and Industrial Processes: Monitoring VOC emissions from factories, ensuring safe working environments, and controlling gas compositions in chemical processes.

- Urban Air Quality Monitoring: Deploying networks of gas analyzers to assess the levels of common air pollutants in major cities, providing data for public health initiatives and policy development.

- Waste Management: Monitoring landfill gases (methane, CO2) for safety and potential energy recovery.

- Research and Academia: Utilizing advanced gas analyzers for scientific studies related to air pollution, climate change, and industrial processes.

Maintenance and Calibration:

Regular maintenance and calibration are essential for ensuring the accuracy and reliability of gas analyzers. This includes:

- Sensor Replacement: Electrochemical and other sensors have a limited lifespan and need periodic replacement.

- Filter Cleaning or Replacement: To prevent particulate matter from interfering with measurements.

- Calibration: Using certified calibration gases to adjust the analyzer’s readings and ensure they are accurate. The frequency of calibration depends on the type of analyzer, its application, and regulatory requirements.

- Regular Checks: Verifying proper operation, battery levels (for portable devices), and data logging.

Conclusion:

Gas analyzers are indispensable tools for environmental and process monitoring, providing critical data for safety, regulatory compliance, process optimization, and environmental protection. The selection of the appropriate analyzer depends on the specific application requirements and a thorough understanding of the different technologies available. In a country like Nigeria with significant industrial activity and growing environmental concerns, the effective deployment and maintenance of gas analysis instrumentation are vital for sustainable development and public well-being.

2. Vibration Monitoring

Vibration Monitoring

Vibration monitoring is the process of measuring and analyzing the vibrations of machinery and structures to assess their condition, identify potential faults, and predict failures. It is a key component of predictive maintenance (PdM) programs, which aim to improve equipment reliability, reduce downtime, and optimize maintenance costs. By continuously or periodically monitoring vibration levels and patterns, it is possible to detect early signs of deterioration in rotating equipment like pumps, motors, turbines, compressors, and gearboxes.

Importance of Vibration Monitoring:

- Early Fault Detection: Vibration analysis can identify developing faults such as bearing defects, imbalance, misalignment, looseness, and gear mesh problems long before they lead to catastrophic failures.

- Reduced Downtime: By addressing issues in their early stages, planned maintenance can be scheduled, minimizing unexpected breakdowns and costly downtime.

- Improved Equipment Reliability and Lifespan: Identifying and correcting vibration-related problems can extend the operational life of machinery and improve overall reliability.

- Enhanced Safety: Monitoring critical equipment can prevent failures that could lead to hazardous situations.

- Optimized Maintenance Costs: Predictive maintenance based on vibration monitoring reduces unnecessary scheduled maintenance and focuses resources on equipment that actually needs attention.

- Process Optimization: In some processes, vibration can affect product quality. Monitoring and controlling vibration can lead to improved product consistency.

Principles of Vibration:

Vibration is the oscillatory motion of a body about a reference position. It can be characterized by several parameters:

- Displacement: The distance traveled by the vibrating object from its equilibrium position.

- Velocity: The rate of change of displacement with respect to time.

- Acceleration: The rate of change of velocity with respect to time. Acceleration is often the preferred parameter for detecting early-stage faults as it is more sensitive to high-frequency vibrations associated with defects like bearing wear.

- Frequency: The number of complete cycles of vibration that occur per unit of time, usually measured in Hertz (Hz) or cycles per minute (CPM). Different mechanical faults generate vibrations at characteristic frequencies.

- Amplitude: The peak or root mean square (RMS) value of displacement, velocity, or acceleration, indicating the severity of the vibration.

- Phase: The relative timing of different vibration signals, which can provide information about the nature and location of a fault.

Vibration Monitoring Instrumentation:

A range of instruments and techniques are used for vibration monitoring:

Accelerometers: These are transducers that convert mechanical vibrations into electrical signals proportional to acceleration. They are the most common type of vibration sensor due to their wide frequency range, sensitivity, and robustness. Accelerometers are typically mounted directly on the machine casing or bearing housing using various methods like stud mounting, magnetic bases, or adhesives

Velocity Transducers (Velometers): These sensors directly measure the velocity of vibration. They typically consist of a coil and a magnet, where the relative motion between them due to vibration induces a voltage proportional to the velocity. While robust and self-powered, they generally have a lower high-frequency response compared to accelerometers and are less commonly used for high-speed machinery analysis.0

Proximity Probes (Eddy Current Sensors): These non-contact sensors measure the relative distance between the probe tip and a conductive surface (usually a rotating shaft). They are primarily used to monitor shaft vibration and position in rotating machinery like turbines and compressors. Changes in the magnetic field generated by the probe due to shaft vibration induce eddy currents in the shaft surface, which are then measured and correlated to the displacement.

Portable Vibration Meters/Analyzers: These handheld devices are used for route-based data collection. A technician visits pre-determined measurement points on machinery, attaches a sensor (typically an accelerometer), and records vibration data. Some advanced portable analyzers can perform on-site analysis, including frequency analysis (FFT spectrum) and time waveform analysis.

Online Vibration Monitoring Systems: These are permanently installed systems that continuously monitor critical machinery. Sensors are fixed at strategic locations, and their signals are transmitted to a central data acquisition system for continuous monitoring, storage, and analysis. Online systems often include alarm capabilities that trigger when vibration levels exceed predefined thresholds.

Data Acquisition Systems: These systems collect and process the signals from vibration sensors. They range from simple data loggers to sophisticated multichannel systems capable of simultaneous data acquisition and advanced signal processing.

Software for Vibration Analysis: Specialized software is used to analyze the collected vibration data. This software can perform various functions, including:

- Time Waveform Analysis: Examining the vibration signal as it varies over time.Frequency Spectrum Analysis (FFT): Decomposing the vibration signal into its constituent frequencies to identify fault frequencies.Trend Analysis: Tracking vibration levels over time to identify changes and predict future trends.Orbit Analysis: For proximity probe data, visualizing the path of the shaft within its bearing clearance.Waterfall Plots and Spectrograms: Displaying how the frequency content of the vibration signal changes over time or operating conditions.Reporting and Alarm Management: Generating reports and triggering alarms based on predefined vibration limits.

Vibration Analysis Techniques:

Analyzing vibration data involves identifying patterns and frequencies that are indicative of specific mechanical faults. Some common fault frequencies are related to:

- Unbalance: Typically occurs at the rotational speed (1x RPM).

- Misalignment: Often দেখা যায় at 1x, 2x, and 3x RPM, possibly with axial components.

- Bearing Defects: Generate high-frequency vibrations related to the bearing’s geometry and rotational speed (Ball Pass Frequency Inner race – BPFI, Ball Pass Frequency Outer race – BPFO, Ball Spin Frequency – BSF, Fundamental Train Frequency – FTF).

- Looseness: Can produce harmonics of the running speed and sub-harmonic frequencies.

- Gear Mesh Problems: Occur at the gear mesh frequency (number of teeth x rotational speed) and its sidebands.

Applications in Nigeria:

Vibration monitoring is crucial in various industries in Nigeria:

- Oil and Gas Industry: Monitoring pumps, compressors, turbines, and generators in refineries, petrochemical plants, and offshore platforms.

- Power Generation: Monitoring turbines, generators, and large pumps in thermal and hydroelectric power plants.

- Manufacturing: Monitoring critical rotating equipment in factories, such as motors, pumps, fans, and machine tools.

- Mining and Cement Industries: Monitoring crushers, conveyors, and rotating equipment in processing plants.

Implementation of a Vibration Monitoring Program:

A successful vibration monitoring program typically involves the following steps:

- Identify Critical Machinery: Determine which equipment is most critical to the operation and would cause significant downtime or safety risks if it failed.

- Establish Baseline Vibration Levels: Collect initial vibration data on new or healthy equipment to serve as a reference for future measurements.

- Select Measurement Points and Sensor Types: Choose appropriate locations on the machinery to mount sensors based on the types of faults expected. Select the suitable type of sensor (accelerometer, velocity transducer, proximity probe).

- Data Collection: Regularly collect vibration data using portable analyzers or rely on continuously collected data from online systems.

- Data Analysis and Interpretation: Analyze the collected data to identify any changes in vibration levels or the appearance of fault frequencies. This requires trained personnel and appropriate software tools.

- Diagnosis and Recommendations: Based on the analysis, diagnose the potential fault and recommend necessary maintenance actions.

- Verification: After maintenance is performed, collect follow-up vibration data to ensure the issue has been resolved.

- Trending and Predictive Analysis: Track vibration trends over time to predict when a fault might become critical, allowing for proactive maintenance planning.

Challenges and Considerations:

- Expertise: Effective vibration analysis requires trained and experienced personnel who can interpret complex vibration data.

- Instrumentation Costs: The initial investment in vibration monitoring hardware and software can be significant.

- Environmental Conditions: Harsh industrial environments can affect the performance and lifespan of vibration sensors.

- Accessibility: Measurement points need to be safely accessible for data collection.

Conclusion:

Vibration monitoring is a powerful tool for predictive maintenance, enabling early detection of mechanical faults, reducing downtime, improving equipment reliability, and enhancing safety in various industries. The effective use of vibration monitoring instrumentation and analysis techniques is essential for optimizing maintenance strategies and ensuring the longevity and efficient operation of critical machinery in Nigeria’s industrial landscape.

3. Environmental Control Systems

Environmental Control Systems

Environmental control systems (ECS) are designed to regulate and maintain specific environmental conditions within a defined space, such as buildings, industrial facilities, or controlled environments like cleanrooms and laboratories. The primary goal of ECS is to provide комфортные and safe conditions for occupants or to ensure optimal conditions for industrial processes, equipment operation, or experimental procedures. These systems typically control parameters like temperature, humidity, air quality (ventilation, filtration, pollutant levels), and pressure.

Importance of Environmental Control Systems:

- Occupant Comfort and Health: Maintaining комфортные temperature and humidity levels, providing adequate ventilation with fresh air, and filtering out pollutants are crucial for the well-being, productivity, and health of building occupants.

- Process Optimization: Many industrial processes require precise control of environmental parameters. For example, in pharmaceutical manufacturing, semiconductor fabrication, and food processing, strict temperature and humidity control are essential for product quality and yield.

- Equipment Protection: Sensitive electronic equipment and machinery often require specific temperature and humidity ranges for reliable operation and to prevent damage.

- Energy Efficiency: Modern ECS are increasingly designed to optimize energy consumption while maintaining desired environmental conditions, contributing to sustainability and cost savings.

- Safety and Compliance: In certain environments, such as hospitals, laboratories handling hazardous materials, and industrial plants with potential airborne contaminants, ECS play a critical role in ensuring safety and regulatory compliance.

- Preservation: Museums, archives, and libraries rely on precise environmental control to preserve sensitive artifacts and documents from deterioration caused by temperature fluctuations, humidity, and pollutants.

Components of a Typical Environmental Control System:

An ECS typically comprises several key components working together:

- Sensors: These devices measure the current environmental conditions, such as temperature, humidity, air pressure, airflow, and air quality parameters (e.g., CO2, VOCs, particulate matter). Different types of sensors are used depending on the specific parameters being monitored and the application requirements.7

- Control Units/Controllers: These are the brains of the ECS. They receive signals from the sensors, compare the measured values to the desired setpoints, and then send control signals to the actuators to adjust the system’s operation and maintain the desired conditions. Controllers can range from simple thermostats to sophisticated building management systems (BMS) with advanced algorithms and network connectivity.8

- Actuators: These are devices that respond to the control signals from the controller to adjust the physical components of the ECS. Common actuators include:

- Dampers: Used in ductwork to control airflow volume.

- Valves: Used in heating and cooling systems to regulate the flow of fluids (e.g., water, refrigerant).

- Variable Frequency Drives (VFDs): Used to control the speed of motors in fans and pumps, thereby regulating airflow and fluid flow rates.

- Heaters and Coolers: Electric heaters, heat pumps, chillers, and other devices that add or remove heat from the air.

- Humidifiers and Dehumidifiers: Devices that add or remove moisture from the air to control humidity levels.

- Air Handling Units (AHUs): These are central units that condition and circulate air within a building. They typically contain filters, heating and cooling coils, fans, and dampers. AHUs take in outside air and/or recirculated air, filter it, condition it to the desired temperature and humidity, and then distribute it through ductwork to different zones within the building.0

- Heating, Ventilation, and Air Conditioning (HVAC) Systems: This is the broader system that includes the components responsible for heating, cooling, and ventilating the air. It often involves chillers for cooling water, boilers or furnaces for heating water or air, and a network of ductwork and piping for air and fluid distribution. The ECS controls the operation of these HVAC components to achieve the desired environmental conditions.1

- Filtration Systems: These are crucial for maintaining air quality by removing dust, pollen, microbial contaminants, and other particulate matter from the air stream. Filters range from basic dust filters to high-efficiency particulate air (HEPA) filters used in cleanrooms and healthcare facilities. Activated carbon filters may also be used to remove odors and gaseous pollutants.2

- Ventilation Systems: These systems are responsible for bringing fresh outside air into the building and removing stale or contaminated indoor air. Proper ventilation is essential for diluting indoor pollutants, controlling humidity, and providing oxygen. Ventilation can be natural (e.g., through windows and vents) or mechanical (using fans and ductwork). Mechanical ventilation systems can be supply-only, exhaust-only, or balanced (both supply and exhaust). Heat recovery ventilators (HRVs) and energy recovery ventilators (ERVs) can be used to improve energy efficiency by transferring heat or both heat and moisture between the incoming and outgoing air streams.3

Types of Environmental Control Systems:

ECS can be classified based on their application and the level of control they provide:

- Comfort Control Systems: Primarily focused on maintaining комфортные conditions for building occupants in residential, commercial, and institutional buildings.

- Process Control Systems: Designed to provide precise environmental conditions required for specific industrial processes, often found in manufacturing plants, pharmaceutical facilities, and semiconductor cleanrooms.

- Building Automation Systems (BAS) or Building Management Systems (BMS): Integrated systems that control and monitor various building services, including HVAC, lighting, security, and fire safety. They often incorporate sophisticated control strategies for energy optimization and operational efficiency.

- Standalone Control Systems: Localized control systems for individual units or zones, such as a thermostat controlling a single HVAC unit.

Applications in Nigeria:

Effective environmental control systems are increasingly important in Nigeria due to its climate and growing industrial and commercial sectors:

- Commercial Buildings and Offices: Ensuring комфортные working environments in office buildings, shopping malls, hotels, and educational institutions, which can significantly impact productivity and customer satisfaction.

- Healthcare Facilities: Maintaining sterile and controlled environments in hospitals, clinics, and laboratories to prevent infections and ensure the proper functioning of medical equipment.

- Pharmaceutical and Food Processing Industries: Providing strict temperature and humidity control to maintain product quality, prevent spoilage, and comply with regulatory standards.

- Data Centers and Telecommunication Facilities: Regulating temperature and humidity to prevent overheating and ensure the reliable operation of sensitive electronic equipment.

- Manufacturing Plants: Controlling environmental conditions that can affect production processes and the quality of manufactured goods.

- Agriculture: In controlled environment agriculture (CEA) like greenhouses and vertical farms, ECS are used to optimize growing conditions for crops.

- Residential Buildings: More widespread adoption of air conditioning and ventilation systems in homes to improve comfort, especially in hotter regions.

Energy Efficiency in Environmental Control Systems:

Energy efficiency is a major consideration in the design and operation of modern ECS. Strategies to improve energy efficiency include:

- Using high-efficiency HVAC equipment.

- Implementing zoning and variable air volume (VAV) systems to condition only occupied spaces.

- Employing economizers to use outside air for cooling when conditions are favorable.

- Optimizing control strategies using advanced algorithms and occupancy sensors.

- Improving building insulation to reduce heating and cooling loads.

- Utilizing heat recovery and energy recovery ventilation systems.

- Regular maintenance and calibration of ECS components.

Challenges and Considerations in Nigeria:

- Power Supply Reliability: Fluctuations and outages in the power supply can significantly impact the operation and lifespan of ECS equipment. Backup power systems are often necessary.

- Climate: The hot and humid climate in many parts of Nigeria presents significant challenges for maintaining комфортные indoor conditions and can increase energy consumption for cooling.

- Availability of Skilled Technicians: Installation, maintenance, and troubleshooting of sophisticated ECS require trained technicians.

- Initial Costs: The initial investment in advanced ECS can be a barrier for some applications.

- Dust and Air Quality: High levels of dust and air pollution can impact the performance and maintenance requirements of filtration systems.

Conclusion:

Environmental control systems are essential for creating комфортные, safe, and productive indoor environments and for ensuring the success of many industrial and scientific processes. As Nigeria’s economy grows and concerns about health, productivity, and sustainability increase, the importance of well-designed, efficient, and properly maintained environmental control systems will continue to rise. Understanding the components, types, and applications of ECS is crucial for professionals involved in building design, facility management, industrial operations, and environmental health