Lanxin Rubber & Plastic Technology Co., Ltd., Expands Manufacturing Capabilities for Faster Customized Solutions

Enhanced LSR & Compression Moulding — Enabling Faster Turnarounds & Complex Designs

Albany, NY, August 17, 2025 / 24-7 Press Release / — Lanxin Rubber & Plastic Technology Co., Ltd., a leading custom rubber products manufacturer, has further strengthened its innovation capabilities by adding four state-of-the-art 250T silicone moulding machines.

These new machines combine the advantages of liquid silicone rubber (LSR) injection moulding with compression moulding technology, enabling higher efficiency, improved precision, and greater flexibility in handling complex product designs.

The investment represents a significant step in the company’s strategy to enhance its manufacturing capacity and respond more effectively to the evolving demands of global markets. By integrating these advanced systems, Lanxin aims to provide:

Faster turnaround times for custom orders

Superior quality control through precision moulding technology

Greater design complexity without compromising on durability

Enhanced competitiveness in international markets

“This upgrade reflects our ongoing commitment to innovation and customer satisfaction,” said a spokesperson for Lanxin Rubber & Plastic Technology Co., Ltd. “With these new capabilities, we are well-positioned to deliver higher performance solutions that meet the diverse needs of our global partners.”

The company continues to focus on sustainable growth by combining advanced technology with customer-centric service, ensuring it remains a trusted partner in the custom rubber and silicone manufacturing sector.

Lanxin Rubber & Plastic Technology Co., Ltd., Expands Manufacturing Capabilities for Faster Customized Solutions

Traditional solid silicone processing and liquid silicone molding each have their advantages and limitations. Solid silicone processing is ideal for small-to-medium batch, multi-variant customization, offering low mold costs and flexible color changes, making it widely used in seals, gaskets, and tubing. However, it requires higher manual involvement and has a relatively longer production cycle. Liquid silicone molding, on the other hand, uses fully automated injection to achieve high-precision, fast, and large-scale production with minimal waste and excellent stability, making it perfect for medical devices, baby products, electronic components, and precision automotive parts. Its drawbacks include higher mold investment, higher product cost, and less flexibility in color changes. To combine the strengths of both methods and better serve diverse customer needs, Lanxin Rubber & Plastic Technology Co., Ltd. has added four brand-new 250T silicone molding machines, enabling more efficient, precise, and flexible production.

These new machines use liquid silicone, replacing traditional solid materials, offering better cost-efficiency and superior product quality. With excellent flowability, they can produce complex structures and large-size silicone parts with precise mold filling, minimized parting lines, and enhanced overall integrity and accuracy. High-efficiency automation ensures short molding cycles for large-scale production, while the fully enclosed injection process reduces contamination risks and labor costs. In addition, these machines support diverse customization, allowing adjustments in hardness, color, and special properties such as flame retardancy, conductivity, or high transparency, meeting the needs of various industries.

“This expansion represents more than just new equipment – it’s our commitment to advancing both quality and cost-efficiency,” explained Liu Jun, Application Engineer at Lanxin. “By optimizing manufacturing processes without compromising quality standards, we enable customers to accelerate time-to-market and enhance their competitive edge. Our goal is to be their strategic partner for sustainable growth.”

If you are looking for precision custom plastic parts or silicone rubber componentssend your design files or sample models to the Lanxin team. We will provide you with a quote and customized solutions within 48 hours. Contact us today to start your exclusive custom project.

About Lanxin Rubber & Plastic Technology Co., Ltd.

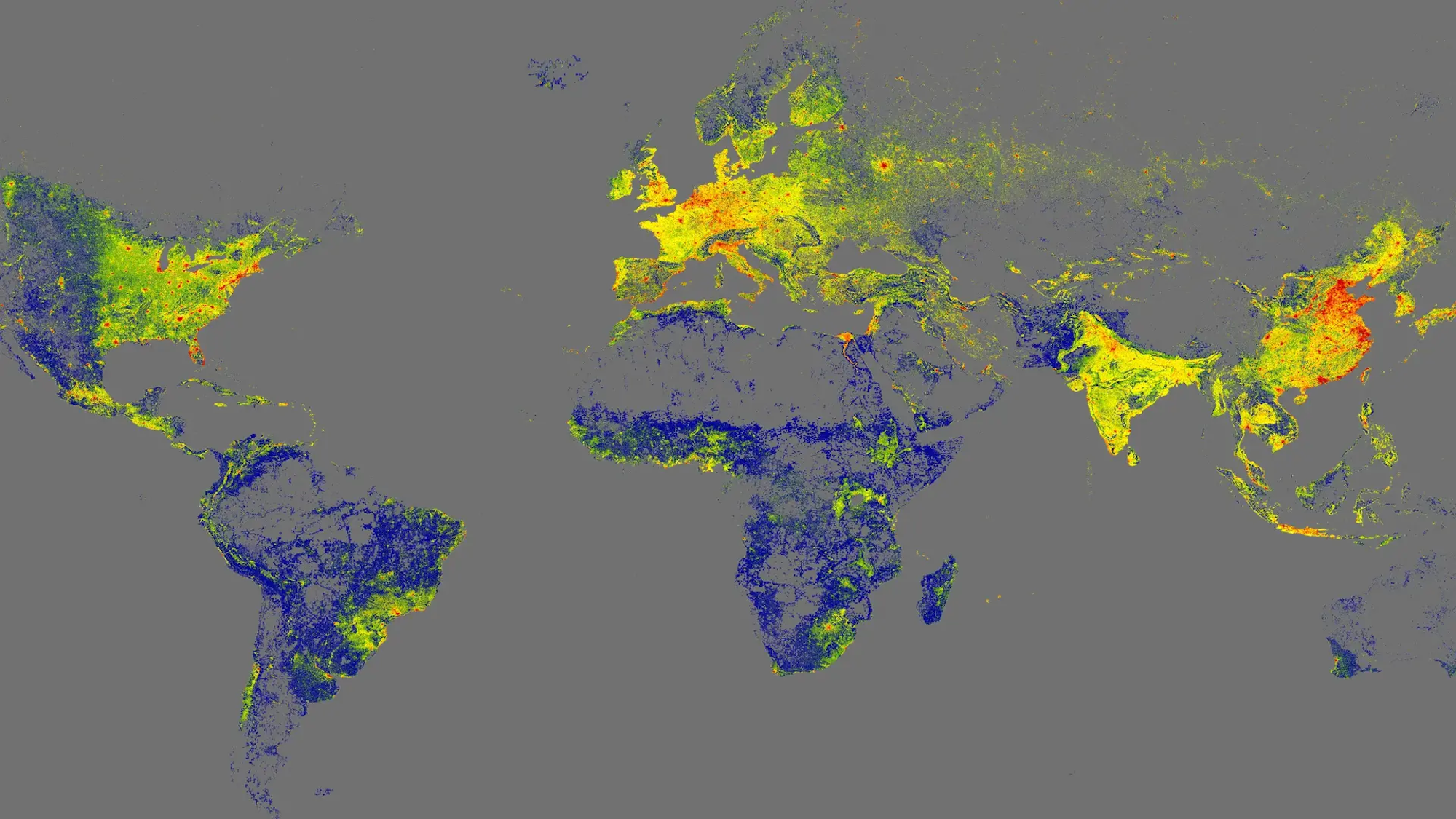

Founded in 1997, Lanxin Rubber & Plastic Technology Co., Ltd. has been delivering high-quality plastic and silicone rubber components for global brands. Headquartered in Dongguan,China, with facilities in Thailand and Vietnam, we offer complete ODM / OEM silicone solutions from design to mass production. Our products serve the medical, automotive, electronics and consumer goods industries, backed by nearly 30 years of manufacturing expertise and certifications including ISO 9001, ISO 14001, ISO 13485, IATF 16949 and LFGB. Trusted by world-leading companies such as Thermo Fisher Scientific, BYD and Honeywell, Lanxin combines innovation, precision and speed to bring your ideas to life.