Blog

Module 3: Temperature Measurement (Contact & Non-Contact)

Introduction

Temperature measurement is a critical aspect of process control in industrial operations, influencing safety, product quality, energy efficiency, and process reliability. Whether monitoring turbine inlet temperatures in power plants, controlling furnace conditions in oil and gas refining, or measuring reactor core heat in nuclear plants, selecting the appropriate temperature measurement method is vital. This training module on “Temperature Measurement” provides an in-depth understanding of both contact and non-contact techniques used across various industries.

Section 1: Fundamentals of Temperature Measurement

Temperature is the measure of the thermal state of a substance, indicating its energy content. Accurate temperature measurement enables optimal process conditions and helps in preventing overheating or undercooling scenarios.

Two Primary Methods of Temperature Measurement:

- Contact Methods: Instruments are in direct contact with the process medium. Examples include RTDs and Thermocouples.

- Non-Contact Methods: Instruments detect emitted infrared radiation from the object. An example is the Infrared (IR) Pyrometer.

Why it Matters:

- Manufacturing: Ensures correct heat treatment, drying, or mixing conditions.

- Oil & Gas: Critical in processes like catalytic cracking and distillation.

- Power Generation: Informs turbine and boiler operation.

- Nuclear Industry: Maintains safe core temperatures.

Section 2: Contact Temperature Measurement

2.1 Resistance Temperature Detectors (RTDs)

RTDs operate on the principle that the electrical resistance of a metal increases with temperature.

Common RTD Types:

- 2-Wire RTD: Simplest configuration, includes measurement error due to lead resistance.

- 3-Wire RTD: Compensates for lead resistance, widely used in industrial applications.

- 4-Wire RTD: Provides highest accuracy by eliminating lead resistance entirely.

Materials Used:

- Platinum (Pt100) is the most widely used due to its stability and linear resistance-temperature relationship.

Applications:

- Power Industry: Steam pipe monitoring.

- Nuclear Industry: Reactor vessel temperature monitoring.

- Manufacturing: Polymer extrusion control.

Animation Suggestion:

- Visual of RTD wire resistance increasing with temperature.

2.2 Thermocouples (T/Cs)

Thermocouples consist of two dissimilar metals joined at one end. They produce a voltage (thermoelectric effect) that correlates to temperature.

Types and Ranges:

- Type J (Iron/Constantan): -40 to 750°C

- Type K (Chromel/Alumel): -200 to 1,260°C

- Type T (Copper/Constantan): -200 to 350°C

- Type S (Platinum Rhodium/Pt): 0 to 1,450°C

- Type R (Platinum Rhodium/Pt): 0 to 1,450°C

- Type B (Platinum Rhodium): 0 to 1,700°C

Animation Suggestion:

- Thermoelectric effect with a voltage loop forming between hot and cold junctions.

Applications:

- Oil & Gas: Furnace and reactor temperature control.

- Power: Turbine exhaust gas monitoring.

- Nuclear: Used with thermowells in high-radiation zones.

2.3 Thermowells

Thermowells protect temperature sensors from harsh environments and allow replacement without process interruption.

Key Considerations:

- Material Selection: Stainless steel, Inconel, Hastelloy (based on corrosion and temperature).

- Insertion Depth: Typically 10x the thermowell diameter or more for accurate readings.

- Mounting Types: Flanged, threaded, or welded.

Visuals & Animations:

- Insertion depth diagram showing correct vs. incorrect immersion.

- Cutaway animation showing flow over a thermowell and the sensor inside.

Common Errors:

- Stem Conduction: Heat travelling along the stem can affect readings.

- Insufficient Immersion: Causes inaccurate measurement.

Section 3: Non-Contact Temperature Measurement

3.1 Infrared Pyrometers

IR pyrometers detect emitted infrared radiation from a surface and calculate temperature based on emission laws (Stefan-Boltzmann and Planck’s Law).

Advantages:

- No physical contact required.

- Fast response time.

- Ideal for moving, hazardous, or inaccessible surfaces.

Considerations:

- Emissivity Settings: Must be adjusted based on material surface.

- Field of View: Sensor should fully encompass the target area.

- Ambient Conditions: Steam, dust, or smoke can affect readings.

Visuals:

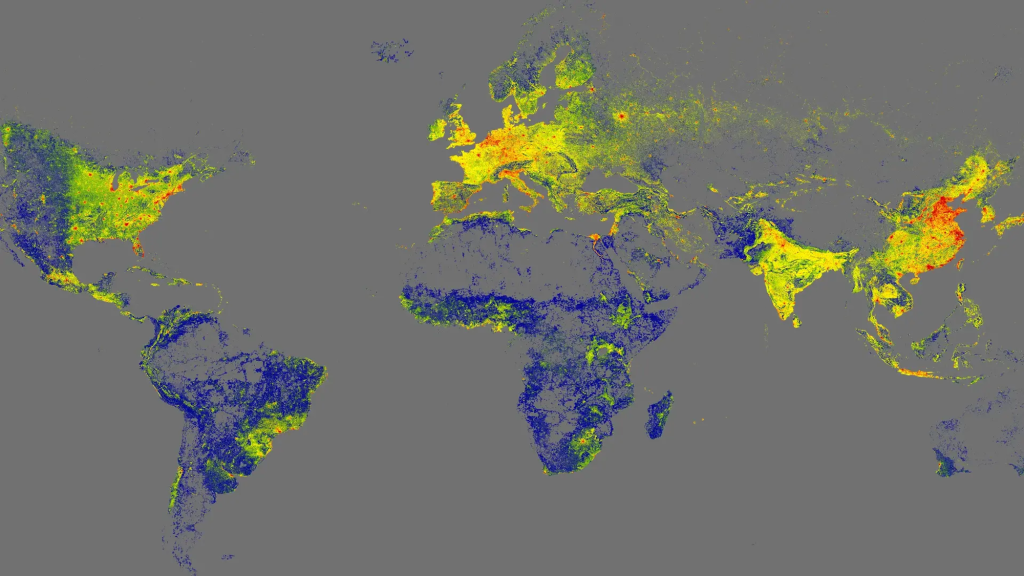

- IR camera heatmaps of turbine blades and furnace walls.

- Targeting diagram showing field of view vs. target size.

Applications:

- Energy Sector: Gas turbine blade inspection.

- Manufacturing: Forging and steel rolling temperature control.

- Oil & Gas: Monitoring flare stack temperatures.

- Nuclear: Remote temperature monitoring in containment zones.

Section 4: Installation Practices and Common Errors

4.1 Installation Guidelines

- Always ensure correct immersion depth (typically 8-10x sensor diameter).

- For RTDs and thermocouples, minimise heat conduction along cables.

- Use appropriate thermowell materials for corrosive or high-temperature fluids.

- Install IR sensors perpendicular to target surface.

4.2 Troubleshooting Common Errors

| Error Type | Cause | Prevention |

|---|---|---|

| Stem Conduction | Thermowell too short or poorly insulated | Use longer wells, minimise conduction paths |

| Ambient Interference (IR) | Dust, moisture, or steam | Use purging or air shields |

| Signal Drift (T/Cs) | Ageing or corrosion of junctions | Schedule regular calibration |

| Loose Connections | Poor wiring of 2-wire/3-wire RTDs | Follow manufacturer wiring standards |

Visuals:

- Side-by-side illustrations of proper vs. improper installations.

- Thermowell stress failure due to improper design (e.g., vortex-induced vibrations).

Section 5: Industry-Specific Case Studies

5.1 Power & Energy: Turbine Inlet and Exit Temperatures

Accurate monitoring improves turbine efficiency and extends component life. Type K thermocouples are widely used due to their high-temperature range and durability.

Tools Used:

- Type K thermocouples, IR pyrometers, 3-wire RTDs

5.2 Oil & Gas: Furnace and Cracking Unit Monitoring

Furnace tube temperatures must be tightly regulated. Thermowells with RTDs and remote IR pyrometers are standard.

Tools Used:

- Type S thermocouples in thermowells, emissivity-adjusted IR sensors

5.3 Nuclear: Reactor Core and Containment Monitoring

High accuracy and reliability are critical. RTDs and thermocouples in sealed, shielded thermowells ensure precision.

Tools Used:

- 4-wire RTDs, Type R/B thermocouples

5.4 Manufacturing: Batch Process Temperature Control

From food processing to plastics, temperature affects quality. Rapid-response IR sensors and RTDs dominate.

Tools Used:

- Platinum RTDs, laser-guided pyrometers

Conclusion

Temperature measurement is indispensable in industrial instrumentation. Mastery of contact methods like RTDs and thermocouples, along with non-contact options like IR pyrometers, enables engineers and technicians to optimise processes, enhance safety, and reduce energy consumption. Understanding installation best practices and avoiding common errors further ensures reliable data.

Next Steps for Learners:

- Practise identifying appropriate sensor types for various applications.

- Participate in a hands-on lab for RTD and thermocouple wiring.

- Engage in simulation exercises using thermal imaging tools.

Interactive Elements to Include:

- Animated videos on:

- Thermoelectric effect (T/C)

- RTD resistance-temperature curve

- IR pyrometer operation

- Image Gallery:

- Field-installed sensors in oil & gas refineries

- Thermowell configurations

- IR heatmaps from manufacturing lines

- Quiz Questions:

- Match sensor to application

- Identify installation faults from diagrams

- Calculate expected resistance of RTD at known temperatures

References:

- Bentley, J. P. (2005). Principles of Measurement Systems. Pearson Education.

- Doebelin, E. O. (2004). Measurement Systems: Application and Design. McGraw Hill.

- ISA (International Society of Automation) Standards and Best Practices.

- Omega Engineering Technical Resources.

End of Module 3 – Tamfitronics.com Training Series