How AI is Transforming Industrial Automation

For decades, industrial automation has been the backbone of manufacturing and production, driving efficiency, consistency, and scale. From the earliest programmable logic controllers (PLCs) to sophisticated robotic arms, these technologies have revolutionised how we create and distribute goods. But a new wave of innovation is crashing onto the factory floor: Artificial Intelligence (AI).

AI is no longer a futuristic fantasy; it’s a tangible force reshaping the landscape of industrial automation, promising unprecedented levels of intelligence, adaptability, and optimisation. In Nigeria, where manufacturing and resource processing play a crucial role in the economy, understanding and embracing this transformation is paramount for future growth and competitiveness.

This blog post will delve into the key ways AI is revolutionizing industrial automation, exploring its applications, benefits, and the exciting future it holds.

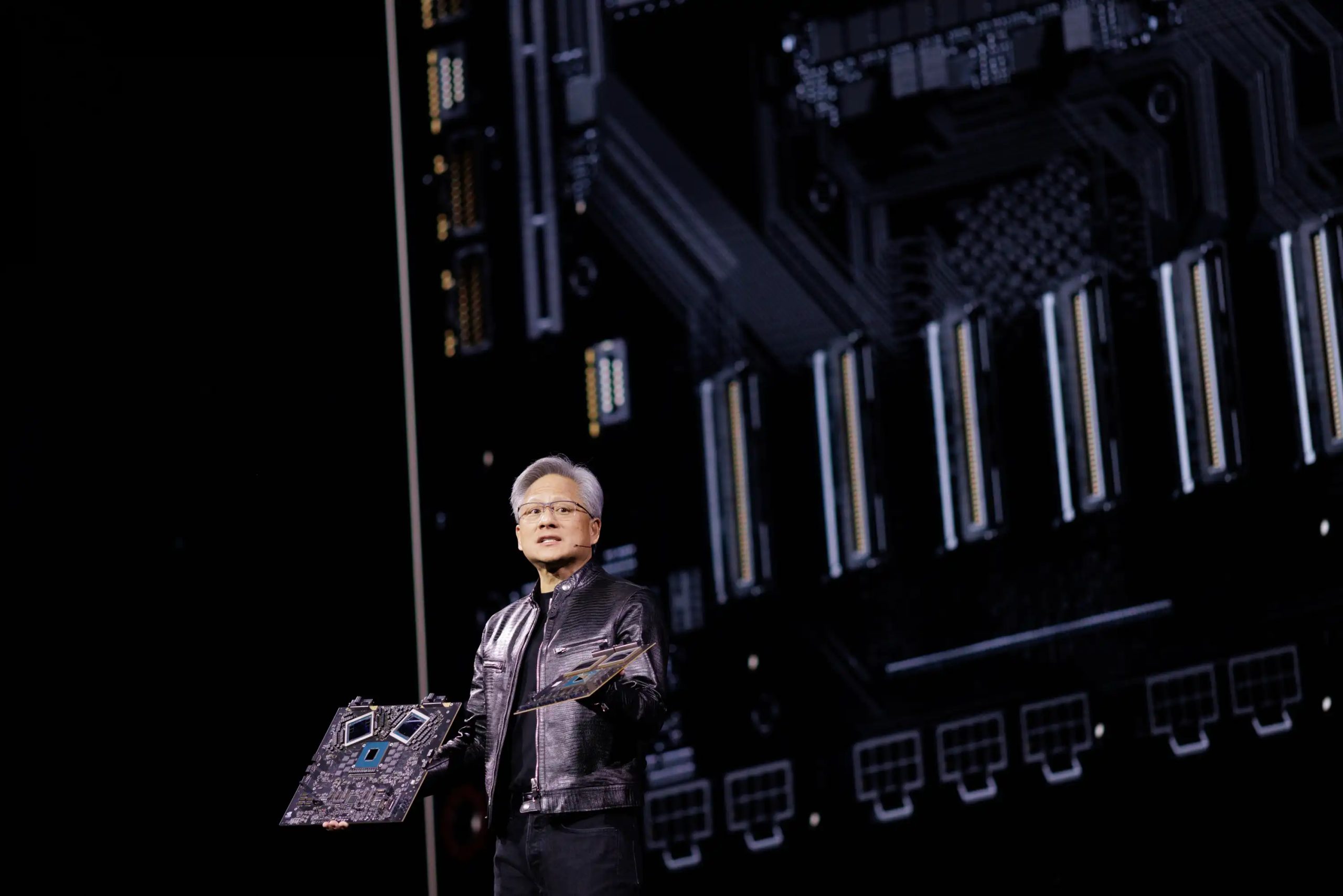

1. Intelligent Robotics: Beyond Repetitive Tasks

Traditional industrial robots excel at performing repetitive, pre-programmed tasks with precision. However, they often lack the ability to handle variability, adapt to new situations, or learn from experience. AI is changing this paradigm, giving robots the “brains” to perceive, reason, and act intelligently.

- Computer Vision for Enhanced Inspection and Quality Control: AI-powered computer vision systems can analyze visual data from cameras to identify defects, anomalies, and deviations in products with far greater accuracy and speed than manual inspection. This is particularly valuable in industries like pharmaceuticals, food and beverage, and electronics manufacturing in Nigeria, where stringent quality standards are essential.

- Adaptive and Collaborative Robots (Cobots): AI enables robots to understand their environment, interact safely with humans, and perform more complex tasks that require dexterity and decision-making. Cobots can work alongside human operators, assisting with assembly, material handling, and other tasks, enhancing productivity and reducing the risk of injury. Imagine such robots assisting in the burgeoning manufacturing sector in cities like Lagos and Kano.

- Autonomous Mobile Robots (AMRs) for Logistics and Material Handling: Equipped with AI-powered navigation and obstacle avoidance, AMRs can autonomously transport materials, parts, and finished goods within a factory or warehouse. This streamlines logistics, reduces bottlenecks, and improves overall efficiency, which can significantly benefit the supply chains within Nigeria’s diverse industrial landscape.

2. Predictive Maintenance: Preventing Downtime Before It Happens

Unplanned downtime in industrial operations can lead to significant financial losses and disruptions. AI-powered predictive maintenance leverages sensor data, machine learning algorithms, and historical records to identify potential equipment failures before they occur.

- Analyzing Sensor Data for Anomaly Detection: AI algorithms can analyze vast amounts of data from sensors monitoring temperature, vibration, pressure, and other parameters to detect subtle anomalies that may indicate an impending failure.

- Predicting Remaining Useful Life (RUL): By learning patterns from historical failure data and real-time sensor readings, AI can estimate the remaining useful life of equipment components, allowing for proactive maintenance scheduling.

- Optimizing Maintenance Schedules and Resource Allocation: Predictive maintenance helps optimise maintenance schedules, ensuring that maintenance is performed only when needed, reducing unnecessary interventions and minimizing downtime. This can be particularly impactful in Nigeria’s oil and gas sector, where equipment reliability is critical.

3. Enhanced Process Optimisation and Control

AI algorithms can analyze complex industrial processes, identify areas for improvement, and optimize control parameters in real-time, leading to increased efficiency, reduced waste, and improved product quality.

- AI-Powered Process Monitoring and Adjustment: AI systems can continuously monitor process variables and automatically adjust control parameters to maintain optimal performance, even in the face of changing conditions or raw material variability. This can be crucial in industries like cement manufacturing and food processing in Nigeria, where consistent product quality is paramount.

- Demand Forecasting and Production Planning: AI can analyse historical sales data, market trends, and other factors to generate more accurate demand forecasts, enabling manufacturers to optimise production planning, reduce inventory costs, and avoid stockouts.

- Energy Optimisation: AI algorithms can analyze energy consumption patterns in industrial facilities and identify opportunities to reduce energy usage, leading to significant cost savings and a reduced environmental footprint – a growing concern globally and within Nigeria.

4. Improved Human-Machine Interaction and Worker Safety

AI is also enhancing how humans interact with industrial automation systems, making them more intuitive, user-friendly, and safer.

- Natural Language Processing (NLP) for Voice Control and Human-Robot Communication: NLP enables workers to interact with robots and automation systems using natural language commands, simplifying operation and reducing the need for complex programming.

- AI-Powered Safety Systems: Computer vision and other AI techniques can be used to monitor worker safety, detect hazardous situations, and issue warnings, reducing the risk of accidents in industrial environments. This is particularly important in industries with inherent safety risks, such as mining and construction in Nigeria.

- Personalised Training and Assistance: AI-powered training platforms can provide personalised guidance and support to workers, helping them develop the skills needed to operate and maintain increasingly complex automation systems.

The Benefits of AI in Industrial Automation: A Nigerian Perspective

For Nigeria’s industrial sector, the adoption of AI in automation offers a multitude of potential benefits:

- Increased Productivity and Efficiency: AI-powered robots and optimised processes can significantly boost production output and reduce waste, leading to higher overall efficiency.

- Improved Product Quality and Consistency: AI-driven quality control systems ensure higher levels of accuracy and consistency in manufacturing processes.

- Reduced Operational Costs: Predictive maintenance minimises downtime and unnecessary repairs, while energy optimisation and efficient resource utilisation lower operational expenses.

- Enhanced Worker Safety: AI-powered safety systems create a safer working environment for industrial workers.

- Greater Competitiveness: By embracing AI, Nigerian industries can become more competitive in both domestic and international markets.

- Job Creation in New Areas: While some routine tasks may be automated, AI will also create new jobs in areas such as AI development, data science, and advanced robotics maintenance.

Challenges and the Path Forward in Nigeria

While the potential of AI in industrial automation is immense, there are also challenges to consider for its successful adoption in Nigeria:

- Infrastructure Limitations: Reliable power supply and robust internet connectivity are crucial for deploying and operating AI-powered systems. Addressing these infrastructure gaps is essential.

- Skills Gap: A shortage of skilled professionals in areas like AI, data science, and robotics could hinder adoption. Investing in education and training programs is crucial.

- Cost of Implementation: The initial investment in AI-powered automation systems can be significant, particularly for smaller businesses. Government support and financing options may be needed.

- Data Privacy and Security Concerns: As industrial systems become more connected and data-driven, ensuring data privacy and security is paramount.

Despite these challenges, the potential rewards of embracing AI in industrial automation for Nigeria are too significant to ignore. By strategically investing in infrastructure, education, and supportive policies, Nigeria can harness the power of AI to transform its industrial sector, drive economic growth, and create a more prosperous future.

Conclusion

AI is no longer a futuristic concept; it is actively reshaping the landscape of industrial automation, offering unprecedented opportunities for efficiency, productivity, and innovation. For Nigeria, embracing this technological revolution is not just an option, but a necessity for achieving its industrial ambitions and competing in the global economy. By understanding the transformative power of AI and proactively addressing the associated challenges, Nigeria can unlock a new era of industrial growth and prosperity.

What are your thoughts on the role of AI in the future of Nigerian industry? Share your opinions and insights in the comments below!

Stay tuned for our next blog post where we will explore specific case studies of AI implementation in different industries within Nigeria.