Specialised Electrical Applications and Innovations: The Future of Electrification

The dynamic landscape of electrical engineering is constantly evolving, pushing the boundaries of what’s possible and reshaping how we interact with technology and energy. Beyond the foundational principles and established systems, a myriad of specialised electrical applications and innovations are emerging, driven by the relentless pursuit of efficiency, intelligence, and sustainability. These cutting-edge advancements are not just theoretical concepts; they are rapidly being integrated into various sectors, from smart infrastructure and advanced manufacturing to critical healthcare and defence.

This section explores some of the most exciting and impactful areas where electrical engineering is making a profound difference. We’ll delve into the intricate world of building automation, the power and precision of uninterruptible power supplies, the unique demands of marine and aviation electrical systems, the sophisticated realm of medical electrical equipment, and the transformative potential of smart grids and electric vehicles. These fields represent the leading edge of electrification, promising a future that is more connected, efficient, and resilient.

Intelligent Infrastructure: Building Automation Systems (BAS/BMS)

Modern buildings are no longer just static structures; they are dynamic, responsive environments, increasingly managed by sophisticated Building Automation Systems (BAS), often referred to as Building Management Systems (BMS) in the UK. These intelligent, computerised networks control and monitor a building’s mechanical and electrical equipment, optimising performance, comfort, safety, and energy efficiency.

Core Functions of a BAS/BMS:

- HVAC Control: Regulating heating, ventilation, and air conditioning systems to maintain desired temperatures and air quality, often with scheduling and occupancy-based control.

- Lighting Control: Managing lighting circuits, including dimming, daylight harvesting, and occupancy sensing, to reduce energy consumption.

- Access Control and Security: Integrating with security systems, CCTV, and access card readers to manage entry and monitor premises.

- Fire and Life Safety: Monitoring fire alarms, smoke detectors, and sprinkler systems, and initiating emergency responses like fan shutdown or elevator recall.

- Power Monitoring and Management: Tracking electricity consumption, power quality, and managing loads to optimise energy use and avoid peak demand charges.

- Utility Metering: Collecting data from electricity, water, and gas meters for billing and performance analysis.

- Elevator/Lift Control: Integrating with lift systems for optimised traffic flow.

Key Components:

- Controllers: Programmable devices (often DDC – Direct Digital Control) that interface with sensors and actuators.

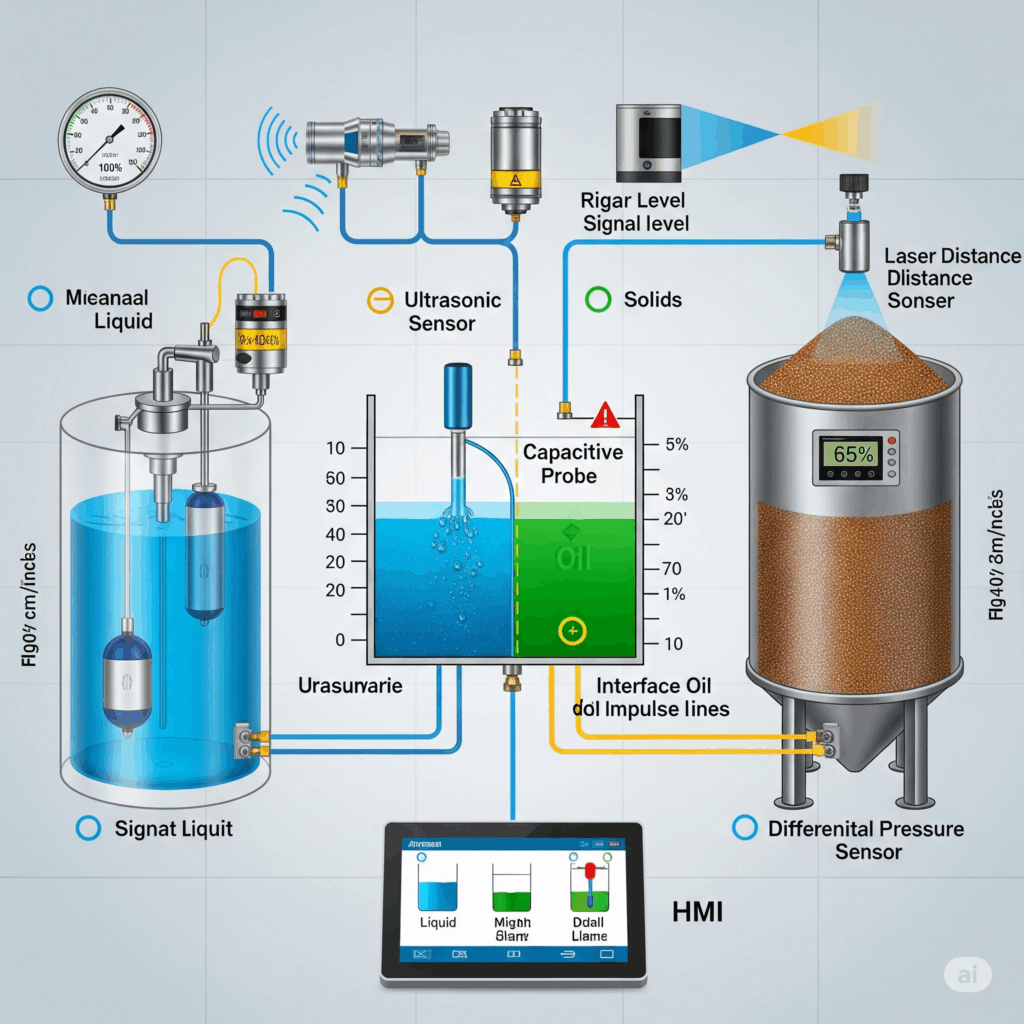

- Sensors: Gather data on temperature, humidity, occupancy, light levels, pressure, etc.

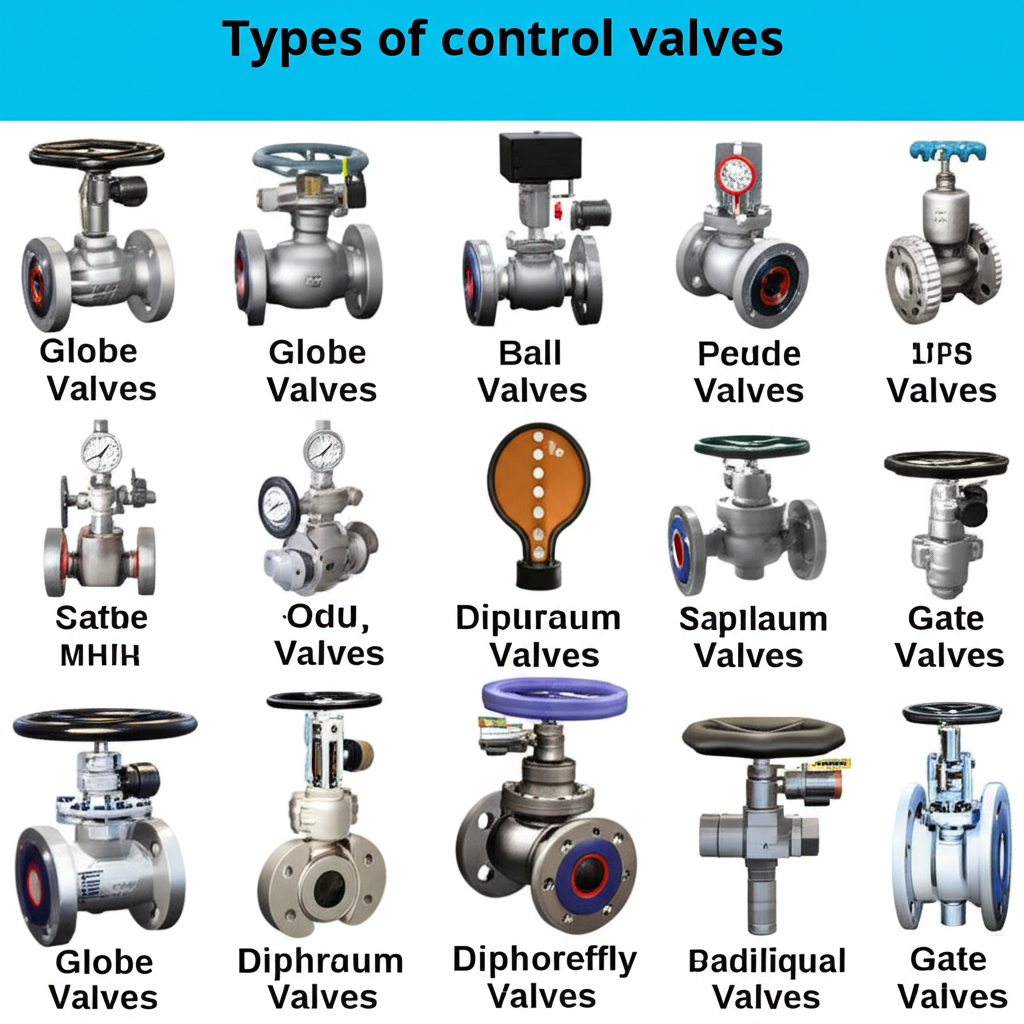

- Actuators: Devices that execute commands from the controllers (e.g., valves, dampers, fan speed controllers, light switches).

- Networking Infrastructure: Communication protocols (e.g., BACnet, Modbus, LONWORKS) that allow components to communicate.

- Centralised Workstation/User Interface: Software that allows operators to monitor, control, and analyse building performance.

Benefits of BAS/BMS:

- Energy Efficiency: Significant reduction in energy consumption (up to 30% or more) by optimising system operation.

- Occupant Comfort: Maintaining consistent environmental conditions.

- Operational Efficiency: Centralised control and monitoring simplify maintenance and troubleshooting.

- Enhanced Safety and Security: Improved response to emergencies and better control over access.

- Data Analytics: Provides valuable data for identifying trends, optimising performance, and predicting maintenance needs.

- Reduced Carbon Footprint: Directly contributes to sustainability goals.

The implementation of BAS/BMS transforms buildings into smart, responsive entities, crucial for modern, energy-conscious infrastructure.

Uninterrupted Power: UPS Systems and Data Centre Power Management

In today’s digital world, where continuity of operations is paramount, Uninterruptible Power Supply (UPS) Systems are indispensable. They provide instantaneous backup power to critical loads in the event of a mains power failure or fluctuation. This is particularly vital in Data Centres, where even a momentary power disruption can lead to data corruption, service outages, and significant financial losses. Data Centre Power Management extends beyond UPS to encompass a holistic approach to power reliability and efficiency.

UPS System Types:

- Offline/Standby UPS: Provides basic surge protection and battery backup. The load normally runs directly from the mains. When the mains fails, an inverter switches on and takes over, with a small transfer time (typically 5-10ms). Suitable for non-critical applications.

- Line-Interactive UPS: A more advanced version of standby UPS. It includes an autotransformer that can regulate voltage fluctuations without switching to battery power, providing better protection against sags and surges. Still has a brief transfer time.

- Online (Double Conversion) UPS: The most robust type, essential for data centres and critical applications. The incoming AC mains is continuously converted to DC, which charges the batteries and simultaneously feeds a DC-to-AC inverter. The inverter then continuously supplies clean, conditioned AC power to the load. In case of mains failure, there is zero transfer time as the batteries seamlessly take over, continuing to supply the inverter. This provides the highest level of power quality and protection.

Key Components of a UPS System:

- Rectifier/Charger: Converts AC to DC to charge batteries.

- Batteries: Store DC energy (typically lead-acid or lithium-ion).

- Inverter: Converts DC back to AC for the load.

- Static Bypass Switch: Allows the load to be transferred directly to the mains if the UPS inverter fails or for maintenance, without interruption.

Data Centre Power Management:

- Redundancy: Implementing N+1, 2N, or 2N+1 redundancy in UPS modules, generators, and distribution paths to ensure that if one component fails, there’s always a backup.

- Generator Integration: Large data centres use diesel generators as a long-term backup, starting up after mains failure to recharge UPS batteries and supply sustained power.

- Power Distribution Units (PDUs): Distribute power efficiently within server racks, often with monitoring capabilities.

- Monitoring Systems: Comprehensive power monitoring of voltage, current, power factor, temperature, and battery health to predict issues and optimise efficiency.

- Harmonic Filtering: To mitigate harmonic distortion caused by non-linear loads (e.g., servers, computers) which can affect power quality.

- Load Balancing: Ensuring loads are evenly distributed across phases to maximise efficiency and prevent overloads.

- Energy Efficiency: Focus on high-efficiency UPS units, cooling systems, and server power supplies to reduce overall energy consumption and operating costs.

Effective UPS systems and meticulous power management are the backbone of data centre reliability, safeguarding invaluable digital assets and ensuring continuous service delivery.

On the Water and In the Air: Marine and Aviation Electrical Systems

Electrical systems in Marine vessels and Aviation aircraft operate under uniquely challenging and highly regulated conditions, demanding unparalleled reliability, redundancy, and robustness. The hostile environments (saltwater, vibration, temperature extremes, high altitude) and the catastrophic consequences of failure necessitate specialised design and rigorous maintenance.

Marine Electrical Systems (Ships, Offshore Platforms):

- Power Generation: Typically use multiple diesel generators (often with redundancy) to provide AC power. Larger vessels might use gas turbines or nuclear power.

- Voltage Levels: Often 440V or 690V three-phase for power distribution, with lower voltages (230V, 110V, 24V DC) for lighting, control, and electronics.

- Distribution: Complex switchboards and motor control centres distribute power throughout the vessel.

- Key Systems:

- Propulsion: Electric motors (often variable speed) driving propellers, particularly in modern vessels.

- Navigation and Communication: Radars, GPS, radio systems, satellite communication.

- Lighting and HVAC: Essential for crew comfort and operational visibility.

- Safety Systems: Fire detection and suppression, emergency lighting, bilge pumps.

- Specialised Equipment: Winches, cranes, cargo pumps, desalination plants.

- Challenges: Corrosive saltwater environment, vibration, space constraints, strict international maritime regulations (e.g., SOLAS, MARPOL, classification societies like Lloyd’s Register), need for redundancy, limited access for repairs at sea.

- Earthing: Often an insulated neutral system for increased resilience to a single earth fault.

Aviation Electrical Systems (Aircraft):

- Power Generation: Primarily AC generators (alternators) driven by the aircraft engines (e.g., Integrated Drive Generators – IDGs) or by Auxiliary Power Units (APUs) on the ground or in flight. Some smaller aircraft use DC generators.

- Voltage Levels: Typically 115V AC, 400Hz (higher frequency for lighter transformers and motors), and 28V DC for various systems.

- Distribution: Highly redundant busbar systems, circuit breakers (often push-pull type), and solid-state power controllers.

- Key Systems:

- Flight Controls: Fly-by-wire systems rely heavily on electrical power.

- Avionics: Navigation, communication, flight management systems, displays.

- Environmental Control: Cabin pressurisation and air conditioning.

- Landing Gear and Flaps: Electrically or electro-hydraulically operated.

- Lighting: Interior and exterior lighting.

- Safety Systems: Fire detection, emergency power, evacuation slides.

- Challenges: Extreme temperatures (from ground to high altitude), pressure changes, vibration, weight constraints (every gram counts), electromagnetic compatibility (EMI) with sensitive avionics, ultra-high reliability requirements, dual/triple redundancy, rigorous certification standards (e.g., FAA, EASA).

- Fault Tolerance: Designed with multiple redundant paths and sophisticated fault detection systems to ensure no single point of failure compromises flight safety.

Both marine and aviation electrical engineers must possess deep expertise in power generation, distribution, control, and stringent safety standards to ensure the continuous and safe operation of these complex, mission-critical systems.

Precision and Protection: Medical Electrical Equipment Standards and Safety

The electrical equipment used in healthcare environments (hospitals, clinics, home care) is subject to the most stringent safety standards due to the direct impact on patient well-being. Medical Electrical Equipment Standards and Safety are paramount, focusing on protecting patients and staff from electric shock, burns, and ensuring reliable operation in critical situations.

Key Risks in Medical Environments:

- Electric Shock to Patients: Patients, especially those undergoing invasive procedures or connected to multiple devices, are highly vulnerable to electric shock (microshock hazard).

- Electromagnetic Interference (EMI): Medical devices can be sensitive to EMI from other electrical equipment, potentially causing malfunctions. Conversely, medical equipment can generate EMI.

- Power Interruption: Loss of power to life-support systems can be fatal.

- Flammable Anaesthetics: Risk of ignition by electrical sparks.

- Cross-Contamination: Equipment must be easily cleanable and sterilised.

Critical Standards and Regulations (e.g., IEC 60601 Series):

The IEC 60601 series of international standards is the primary benchmark for the safety and essential performance of medical electrical equipment. It’s adopted or forms the basis for national regulations worldwide.

- IEC 60601-1 (General Requirements for Basic Safety and Essential Performance): The overarching standard covering electrical safety, mechanical safety, thermal hazards, accuracy of controls, and environmental conditions.

- Collateral Standards (e.g., IEC 60601-1-2 for EMC): Address specific aspects like electromagnetic compatibility (EMC), radiation protection, and alarms.

- Particular Standards (e.g., IEC 60601-2-2 for High Frequency Surgical Equipment): Specific requirements for different types of medical devices.

Key Safety Features and Design Considerations:

- Patient Protection:

- Means of Patient Protection (MOPP): Devices are designed with multiple layers of insulation, protective earthing, or specific isolation transformers to ensure extreme reliability against shock.

- Limited Leakage Current: Very strict limits on earth leakage and patient leakage currents (microamperes) to prevent microshock.

- Isolated Patient Circuits: Patient-connected parts are often electrically isolated from the mains supply.

- Power Reliability:

- UPS Systems: Critical medical equipment is connected to UPS systems to ensure uninterrupted power.

- Dedicated Circuits: Specific medical areas (e.g., operating theatres, intensive care units) have dedicated, often monitored, electrical circuits.

- IT System (Isolated Power System): In operating theatres and critical care areas, an IT earthing system (isolated power system with an isolation transformer and an insulation monitoring device) is often used. This system ensures that a single earth fault does not immediately trip the supply, allowing critical procedures to continue while an alarm is raised.

- Electromagnetic Compatibility (EMC):

- Rigorous testing and design to ensure devices neither emit excessive electromagnetic interference nor are susceptible to interference from other equipment.

- Mechanical and Environmental Robustness:

- Ability to withstand repeated cleaning, disinfectants, and physical handling.

- Resistance to ingress of liquids (e.g., IP ratings).

- User Interface and Alarms:

- Clear, unambiguous controls and reliable alarm systems.

- Maintainability and Servicing:

- Designed for safe and easy maintenance by qualified biomedical engineers.

Compliance with these standards is a complex, multi-faceted process involving design, testing, and documentation. It underlines the commitment to patient safety inherent in the medical electrical equipment industry.

The Network of Tomorrow: Smart Grids and Grid Modernisation

The traditional electricity grid, a largely unidirectional system, is evolving rapidly into a dynamic, two-way network known as the Smart Grid. This modernisation effort leverages advanced digital technologies, communication networks, and intelligent control systems to enhance the reliability, efficiency, security, and sustainability of electricity generation, transmission, and distribution.

Key Characteristics and Technologies of a Smart Grid:

- Two-Way Communication:

- Unlike the traditional grid, the smart grid allows electricity and information to flow in both directions (from utility to consumer, and from consumer/distributed generation back to the utility).

- Advanced Metering Infrastructure (AMI)/Smart Meters: Provide real-time data on consumption, enabling dynamic pricing, remote meter reading, and outage detection.

- Distributed Energy Resources (DERs) Integration:

- Seamless integration of decentralised generation sources like rooftop solar, wind turbines, and battery storage systems directly into the distribution network.

- Microgrids: Self-contained energy systems that can operate independently or connected to the main grid, providing enhanced local reliability.

- Advanced Sensing and Measurement:

- Phasor Measurement Units (PMUs): Provide highly synchronised, real-time measurements of voltage and current phasors across the grid, enabling rapid detection of grid instabilities.

- Sensors throughout the distribution network: For voltage, current, temperature, and fault detection.

- Self-Healing Capabilities:

- Intelligent control systems (often with AI/machine learning) that can automatically detect faults, isolate the problematic section, and reroute power to restore service quickly, minimising outages.

- Demand Response Management:

- Programs that encourage consumers to reduce or shift their energy consumption during peak periods in response to price signals or grid conditions, balancing supply and demand.

- Energy Storage:

- Large-scale battery storage, pumped-hydro storage, or other forms of energy storage integrated into the grid to balance intermittent renewable generation and provide grid stability.

- Cybersecurity:

- Robust cybersecurity measures are paramount to protect the communication networks and control systems from cyber threats.

Benefits of a Smart Grid:

- Improved Reliability and Resilience: Fewer and shorter outages due to self-healing capabilities and redundancy.

- Enhanced Energy Efficiency: Reduced losses, optimised power flow, and better demand management.

- Integration of Renewables: Facilitates the large-scale adoption of intermittent renewable energy sources.

- Reduced Carbon Emissions: By enabling more renewables and improving efficiency.

- Economic Benefits: Lower operating costs for utilities, new services for consumers, and potential for energy bill savings.

- Consumer Empowerment: Greater control and information over energy consumption.

Grid modernisation is a massive undertaking, but it is essential for building a sustainable, reliable, and intelligent energy future.

Driving the Revolution: Electric Vehicles (EVs) and Charging Infrastructure

The rapid rise of Electric Vehicles (EVs) represents a paradigm shift in transportation, moving away from fossil fuels towards electrification. This revolution is fundamentally an electrical engineering challenge, encompassing not only the vehicles themselves but also the vital Charging Infrastructure required to support their widespread adoption.

Electric Vehicle (EV) Electrical Systems:

- Battery Pack: The heart of the EV, typically a large lithium-ion battery pack operating at high DC voltages (e.g., 400V, 800V or higher). Designed for high energy density, power delivery, and safety.

- Electric Motor(s): Convert electrical energy from the battery into mechanical energy to drive the wheels. Often AC induction or permanent magnet synchronous motors.

- Power Electronics (Inverters/Converters):

- Inverter: Converts DC battery power to AC for the electric motor.

- DC-DC Converter: Steps down the high voltage from the battery to power the vehicle’s 12V auxiliary systems.

- On-board Charger (OBC): Converts incoming AC charging power to DC to charge the battery.

- Battery Management System (BMS): A crucial electronic system that monitors individual cell voltage, temperature, and current; balances cells; and protects the battery from overcharge, over-discharge, and overheating, ensuring safety and longevity.

- Regenerative Braking: Electric motors act as generators during braking, recovering kinetic energy and converting it back into electrical energy to recharge the battery, improving efficiency.

EV Charging Infrastructure:

- AC Charging (Level 1 & Level 2):

- Level 1 (Slow): Plugs into a standard domestic 230V AC socket (e.g., BS 1363 in the UK). Very slow (adds ~10-20 km range per hour).

- Level 2 (Medium): Requires a dedicated charging station (often wall-mounted) providing higher AC power (e.g., 7kW, 11kW, 22kW three-phase). Uses Type 2 (Mennekes) connector in Europe/UK. Common for home, workplace, and public charging. Adds ~30-120 km range per hour.

- DC Fast Charging (Level 3 / Rapid Charging):

- Principle: Bypasses the vehicle’s on-board charger and directly delivers DC power to the battery, allowing much faster charging.

- Power Levels: High power (e.g., 50kW, 150kW, 350kW, and beyond).

- Connectors: CCS (Combined Charging System) is dominant in Europe/UK; CHAdeMO (primarily Japanese vehicles); Tesla Supercharger.

- Speed: Can add hundreds of kilometres of range in 15-30 minutes, crucial for long journeys.

- Infrastructure Impact: Requires significant grid upgrades due to high power demand; poses thermal management challenges for both charger and EV battery.

Challenges and Innovations:

- Charging Time: Reducing charging time, especially for long-distance travel.

- Battery Technology: Improving energy density, lifespan, safety, and reducing cost.

- Grid Integration: Managing the increased electrical load on the grid from widespread EV adoption, including smart charging (optimising charging times to reduce grid strain) and Vehicle-to-Grid (V2G) technology (EVs feeding power back to the grid).

- Standardisation: Harmonising charging standards and connectors globally.

- Thermal Management: Efficiently managing heat in battery packs during charging and discharge.

The ongoing development in EV technology and charging infrastructure is a critical driver for sustainable transportation and a key area of focus for electrical engineers.

Protecting Sensitive Electronics: Electrostatic Discharge (ESD) Control

In today’s world, sensitive electronic components are ubiquitous, from the microchips in your phone to the sophisticated control systems in industrial machinery. These components are highly vulnerable to damage from Electrostatic Discharge (ESD), which is the sudden flow of electricity between two electrically charged objects. ESD can occur simply by walking across a carpet and then touching a doorknob (creating a spark), but even discharges too small to be felt by humans can destroy delicate electronics. ESD Control is therefore a vital practice in environments where sensitive electronics are manufactured, handled, or repaired.

How ESD Occurs and Causes Damage:

- Triboelectric Charging: Friction between two materials (e.g., walking, rubbing clothes) causes electrons to transfer, creating a static charge on surfaces or bodies.

- Discharge: When a charged object or person touches a less charged (or oppositely charged) object, electrons rapidly transfer, creating a surge of current.

- Damage: This current surge can melt microscopic pathways within integrated circuits, damage gate oxides, or alter component characteristics, leading to immediate failure or latent damage (which manifests later).

Principles of ESD Control:

The goal of ESD control is to minimise charge generation, safely dissipate charges, and protect sensitive devices from discharge.

- Grounding/Earthing:

- Personnel Grounding: Most critical. Workers wear ESD wrist straps that connect them to a common point ground (via a current-limiting resistor for safety).

- Footwear and Flooring: ESD-safe footwear and conductive or static-dissipative flooring work together to safely dissipate static charges from walking.

- Work Surface Grounding: ESD-safe mats on workbenches are grounded to dissipate charges from tools or components.

- Static-Dissipative Materials:

- Materials that slowly conduct static charges away, preventing rapid discharge. Used for work surfaces, floor mats, and sometimes tools.

- Shielding and Packaging:

- ESD Bags/Containers: Sensitive components are stored and transported in anti-static bags or containers made of conductive or static-dissipative materials to protect them from external static fields and direct discharge.

- ESD Smocks/Lab Coats: Made from static-dissipative fabric to prevent charging on clothing.

- Ionisation:

- Ionisers: Devices that produce a balanced stream of positive and negative ions. These ions neutralise static charges on non-conductive materials (e.g., plastic parts, clothing) that cannot be grounded.

- Humidity Control:

- Higher humidity (e.g., above 50% RH) generally reduces static charge build-up by providing a thin layer of moisture on surfaces, making them more conductive. However, it’s not always sufficient on its own.

- Training and Procedures:

- Regular training for all personnel on ESD awareness, proper handling procedures, and the correct use of ESD control equipment.

- Strict adherence to ESD Protected Area (EPA) protocols.

ESD Protected Areas (EPAs): Dedicated areas where all necessary ESD control measures are in place. Access is often restricted, and personnel must wear specific ESD PPE.

Implementing comprehensive ESD control measures is essential for ensuring the reliability and quality of electronic products and systems, particularly in manufacturing, assembly, and repair facilities.

Discover more from Tamfis Nigeria Limited

Subscribe to get the latest posts sent to your email.

Hot Deals

Hot Deals Shopfinish

Shopfinish Shop

Shop Appliances

Appliances Babies & Kids

Babies & Kids Best Selling

Best Selling Books

Books Consumer Electronics

Consumer Electronics Furniture

Furniture Home & Kitchen

Home & Kitchen Jewelry

Jewelry Luxury & Beauty

Luxury & Beauty Shoes

Shoes Training & Certifications

Training & Certifications Wears & Clothings

Wears & Clothings